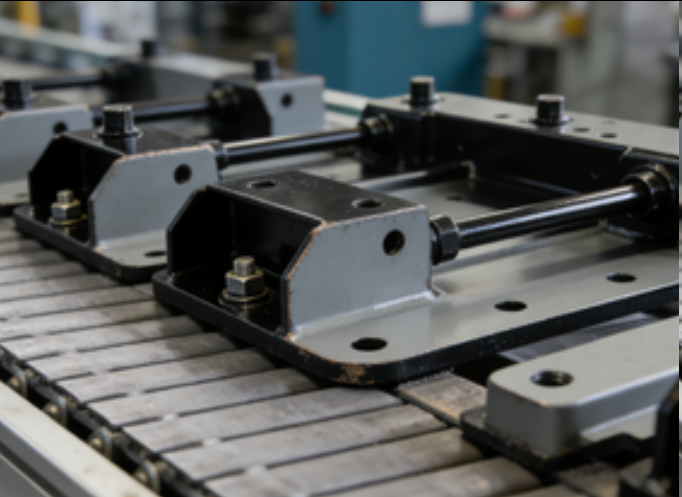

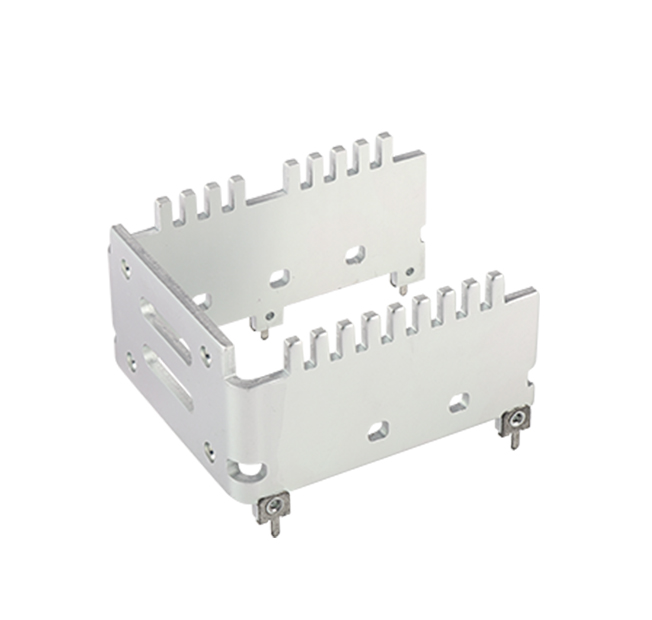

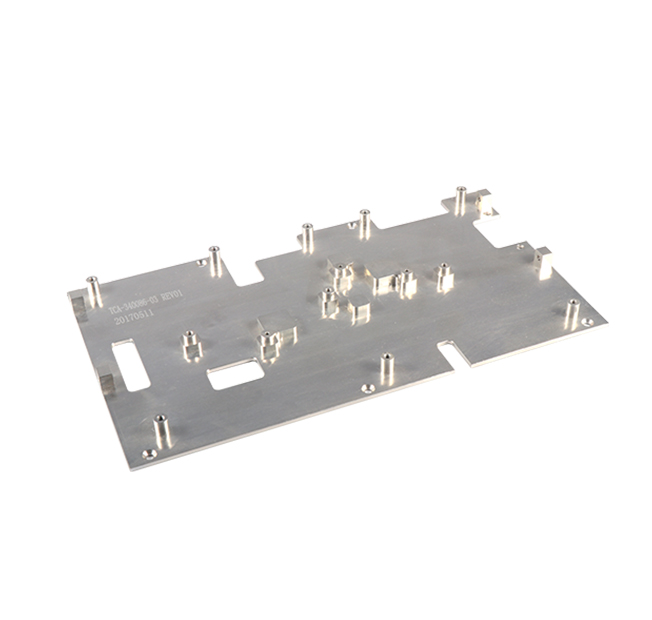

Sheet metal tooling fixtures are essential components in the sheet metal manufacturing process, designed to securely hold, position, and support sheet metal workpieces during various fabrication operations such as cutting, bending, stamping, welding, and assembly. These fixtures play a critical role

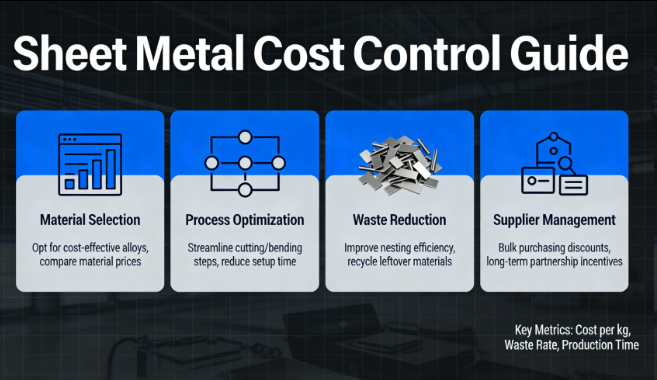

Cost control is a critical priority in sheet metal manufacturing, where profit margins are often constrained by material expenses, labor costs, and competitive pricing pressures. Effective cost control strategies span the entire production lifecycle, from material selection and procurement to manufa

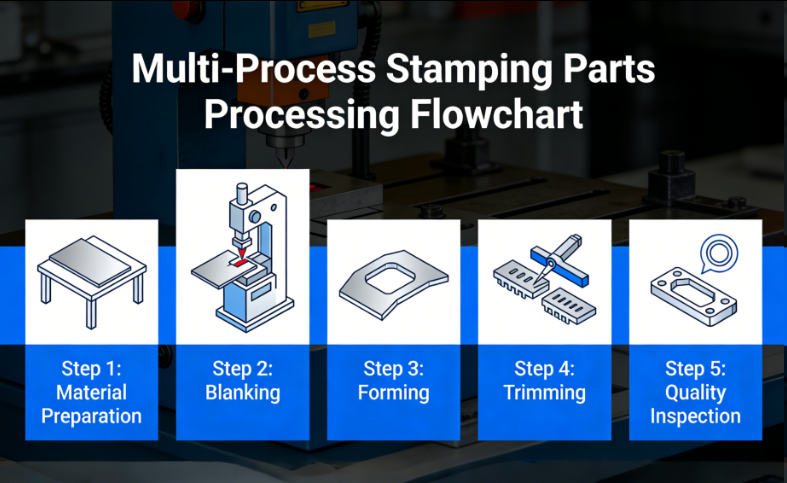

Multi-process stamping, also known as progressive die stamping, is an advanced manufacturing method that combines multiple stamping operations—such as blanking, piercing, bending, drawing, and flanging—into a single, continuous process using a progressive die set. This integrated approach allows a r

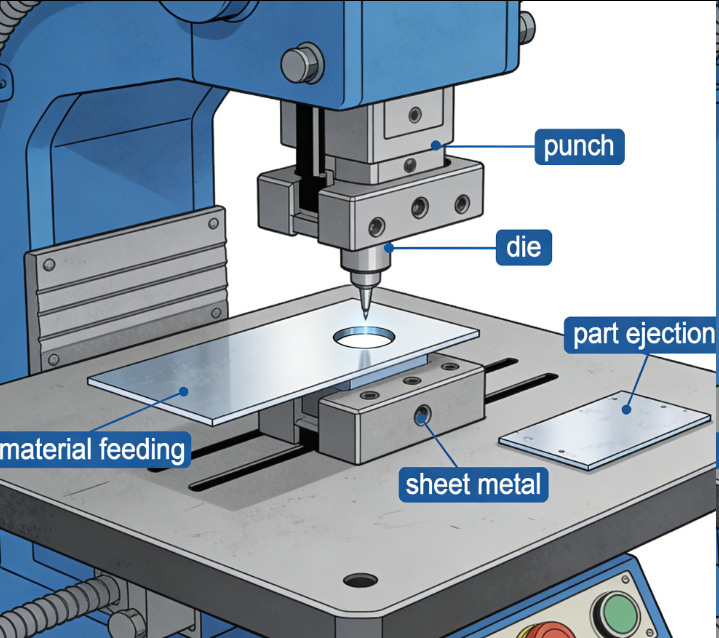

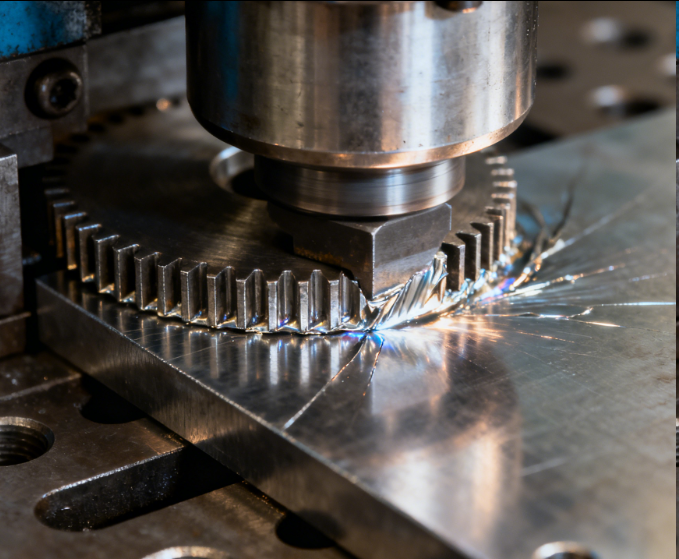

Sheet Metal Punching Processing is a core manufacturing technique used to create precise holes, slots, notches, or custom shapes in sheet metal materials (such as steel, aluminum, copper, and stainless steel) with thicknesses ranging from 0.1mm to 20mm. This process relies on a punch press—a machine

The CNC machining automated workshop represents the forefront of modern manufacturing, integrating cutting - edge technologies to streamline production processes, enhance efficiency, and improve product quality. At the heart of such a workshop lies the seamless coordination of CNC machines, robotic

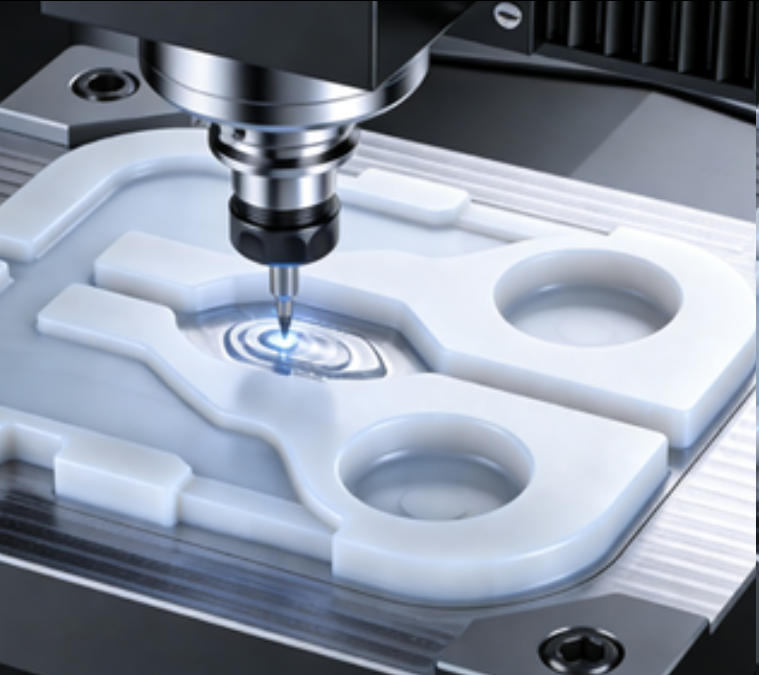

CNC (Computer Numerical Control) machining of engineering plastic parts has become an increasingly popular manufacturing method due to its ability to produce high - precision, complex - shaped components with consistent quality. Engineering plastics are a group of high - performance polymers that of

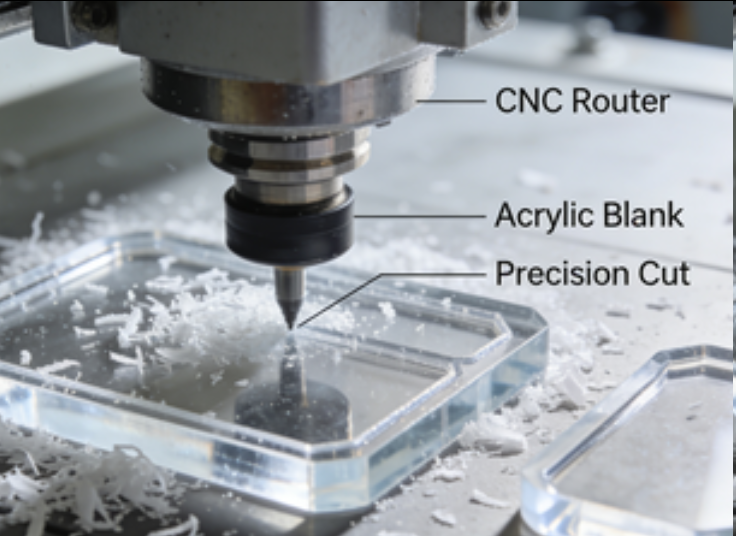

CNC machining of acrylic parts has gained significant popularity across various industries due to the unique properties of acrylic, also known as polymethyl methacrylate (PMMA). Acrylic is renowned for its excellent optical clarity, similar to glass, yet it is much lighter and more shatter - resista

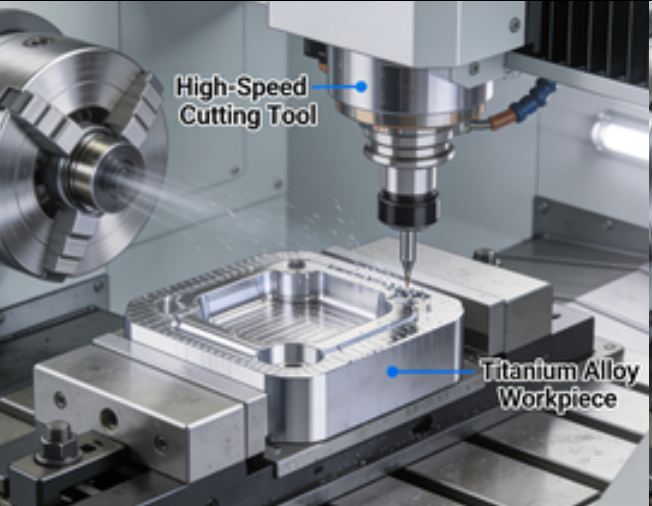

CNC (Computer Numerical Control) machining of titanium alloy parts has become increasingly significant in various high - end industries due to the unique properties of titanium alloys. Titanium alloys are renowned for their high strength - to - weight ratio, excellent corrosion resistance, and good

Sheet metal assembly processing is a crucial stage in the manufacturing of various products, involving the meticulous combination of multiple sheet metal components into a functional and structurally sound unit. This process requires a high level of precision and technical expertise, as the quality

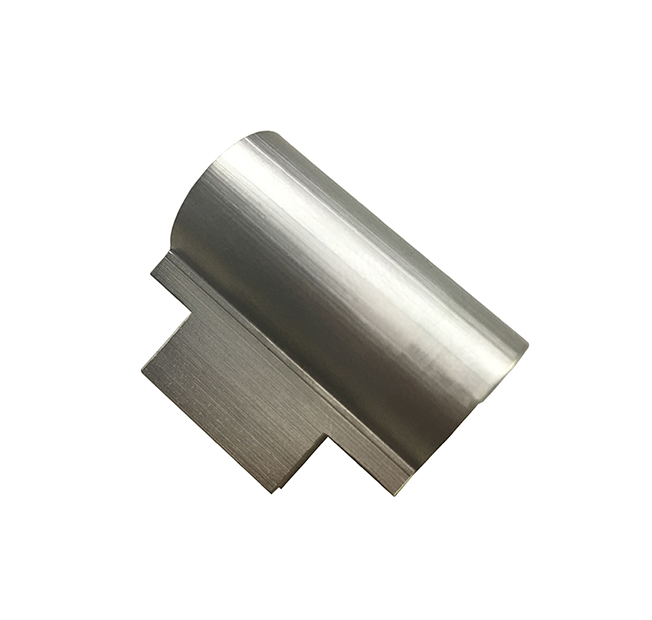

CNC (Computer Numerical Control) machined parts have revolutionized the manufacturing industry by enabling the production of highly complex and precise components with repeatable accuracy. These parts are created through a process where computer - controlled machine tools, such as milling machines,

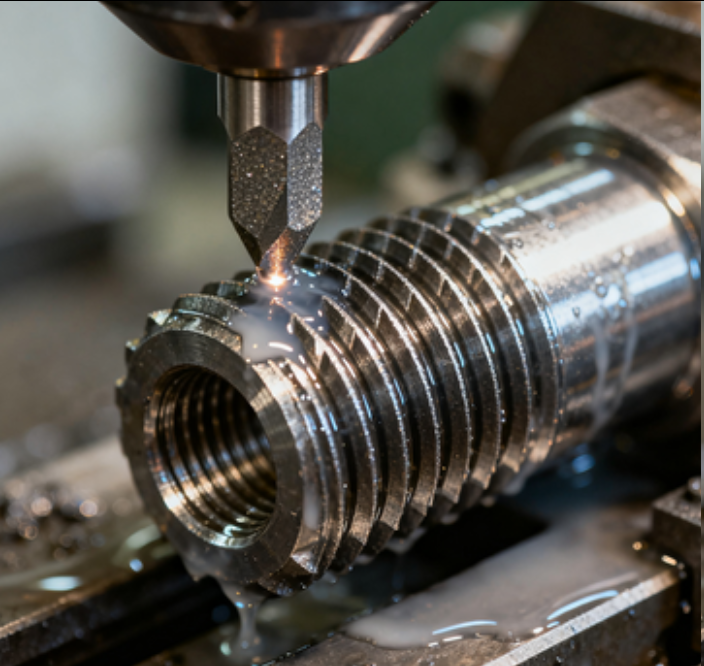

CNC machining of tapped parts is a precise and specialized manufacturing process that plays a crucial role in creating threaded holes, known as tapped holes, in various components. Tapping is essential for assembling parts using screws, bolts, or other threaded fasteners, and CNC technology brings a

Electrophoretic coating, also known as electrocoating, is a highly advanced and efficient surface finishing process specifically tailored for stamping parts. This technique has revolutionized the way stamping parts are protected and enhanced, offering a multitude of benefits that are crucial in vari

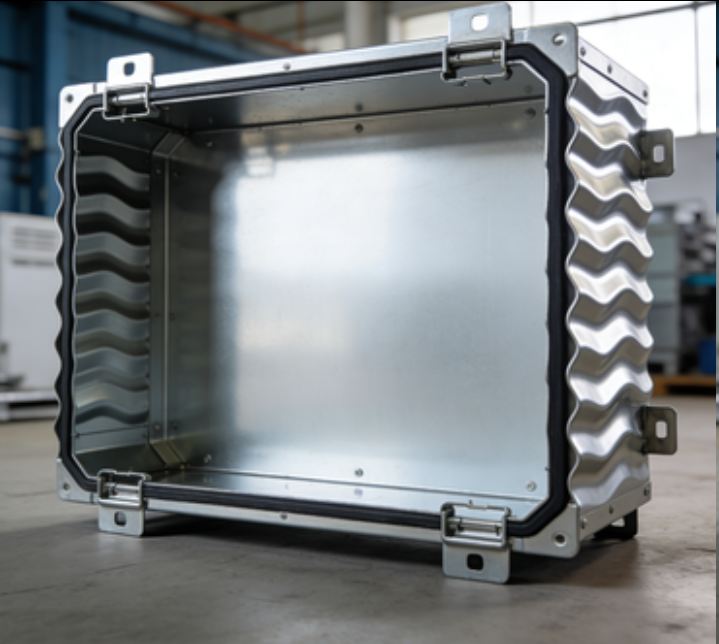

Sheet metal communication base station boxes are integral to the infrastructure of modern communication networks. These boxes house a plethora of critical equipment, including radio transceivers, power amplifiers, and signal processing units, which are essential for the transmission and reception of

Sheet metal marine accessories play a vital role in the construction, operation, and maintenance of ships and other marine vessels. The harsh marine environment, characterized by high humidity, saltwater corrosion, and strong mechanical stresses, demands components that are durable, reliable, and ca

Stamping parts and fine blanking parts processing represents a sophisticated and highly precise manufacturing technique that plays a vital role in various industries. Stamping, as a fundamental metal - forming process, involves the use of dies and presses to shape flat metal sheets into desired form

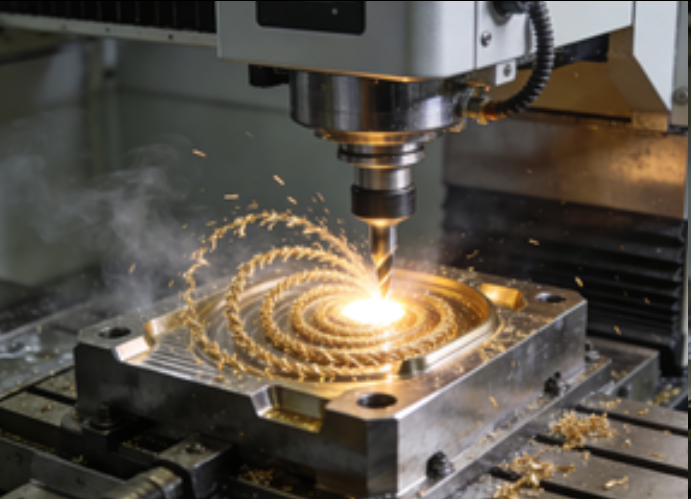

CNC machining high - speed milling represents a cutting - edge manufacturing technology that has revolutionized the production of complex components across various industries. This advanced machining process involves operating computer - numerically controlled (CNC) machines at elevated speeds to ra

Technical support for sheet metal parts is an essential service that encompasses a wide range of expertise and assistance, ensuring the successful design, production, and application of sheet metal components. Sheet metal parts are widely used across various industries, from automotive and aerospace

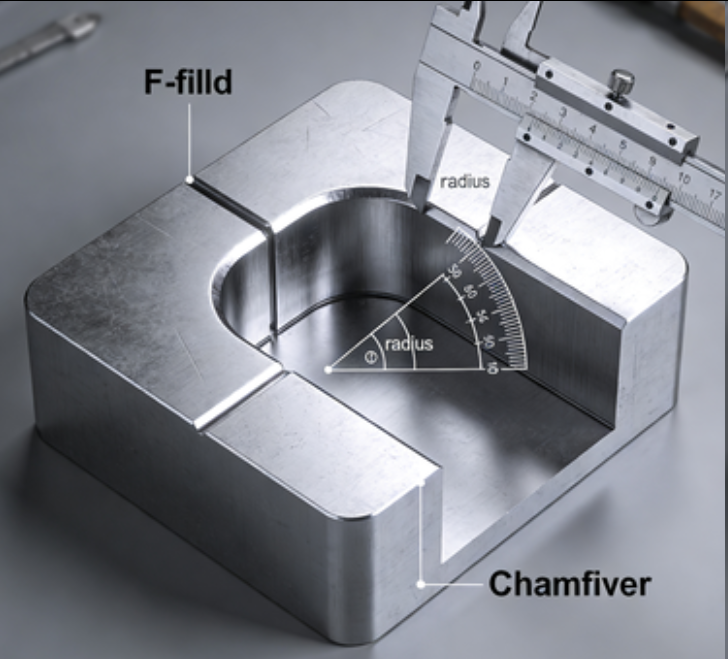

In the manufacturing of stamping parts, the incorporation of R - fillets and chamfering techniques is of great significance, as they not only enhance the aesthetic appeal but also improve the functional performance and durability of the parts. An R - fillet, also known as a rounded corner, is a curv

Stamping parts play a crucial role in modern manufacturing across various industries, and the processes of chamfering and edge deburring are essential steps in enhancing their functionality, safety, and overall quality. Chamfering refers to the process of creating a beveled edge on a stamping part,

CNC (Computer Numerical Control) machining has revolutionized the production of agricultural equipment parts, offering unparalleled precision, efficiency, and flexibility in manufacturing components crucial for modern farming operations. Agricultural equipment, ranging from tractors and harvesters t

Stamping parts play a crucial role in the manufacturing of medical devices, where precision, cleanliness, and biocompatibility are of utmost importance. The medical industry demands components that meet strict regulatory standards and can withstand the rigors of frequent use, sterilization, and expo

Stamping Parts Prototype Production refers to the process of creating small-batch, custom stamping parts to validate design concepts, test performance, and ensure compatibility before full-scale manufacturing. This stage is critical for businesses across industries—from automotive to consumer electr

Stamping parts are essential for manufacturing metal components of public facilities—such as park benches, bus stop shelters, street lamp poles, public restroom fixtures, and playground equipment—providing the durability, weather resistance, and structural stability required for high-traffic, outdoo

Stamping parts play a critical role in the manufacturing of display cabinet metal frames, serving as core structural components that ensure stability, durability, and aesthetic consistency for retail, exhibition, and home storage display cabinets. Unlike traditional welded or cast metal components (

CNC machining has emerged as a transformative force in the manufacturing of lighting fixture accessories, enabling the production of high - quality, precisely crafted components that are essential for both the functionality and aesthetic appeal of modern lighting systems. Lighting fixtures consist o

CNC (Computer Numerical Control) machining has revolutionized the manufacturing of air conditioning accessories, offering unparalleled precision, efficiency, and consistency. Air conditioning systems consist of numerous intricate components, each with specific dimensional and functional requirements

A CNC Machining Non - Disclosure Agreement (NDA) is a legally binding contract between a CNC machining service provider and a client, designed to protect sensitive information shared during the manufacturing process of custom components. In the CNC machining industry, where clients often share pro

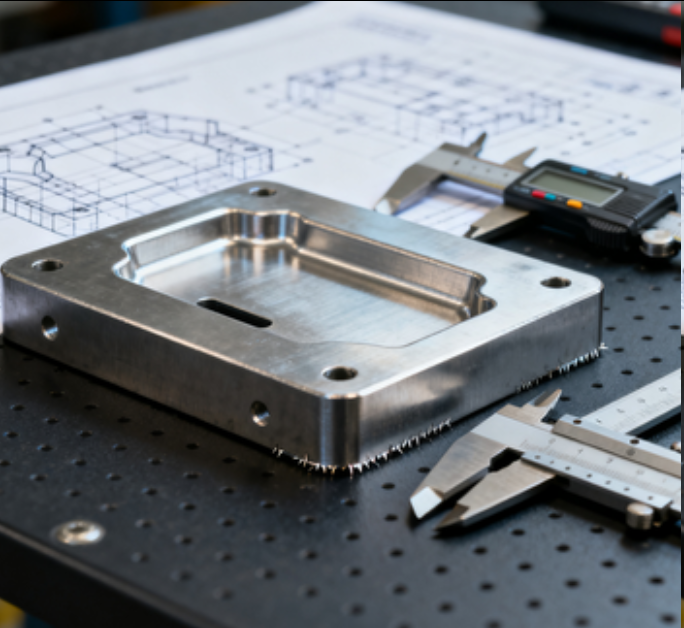

Precision CNC machining services are advanced manufacturing solutions that utilize computer numerical control (CNC) technology to produce high - accuracy components for industries such as aerospace, automotive, medical devices, and electronics. These services stand out for their ability to achieve t

Stamping parts are a fundamental component in the manufacturing of air conditioner (AC) outdoor unit panels—structural and protective covers that shield the unit’s compressors, condensers, and fan systems from external damage, weather, and debris. AC outdoor units operate in harsh outdoor environmen

Stamping parts are a cornerstone in the manufacturing of security equipment enclosures, which house critical devices like surveillance cameras, access control panels, alarm sensors, and intercom systems. These enclosures must meet rigorous standards: they need to be tamper-resistant to deter vandali

Stamping parts play a pivotal role in the manufacturing of solar bracket plates, which are critical components for securing solar panels to rooftops, ground-mounted systems, or tracking structures. Solar bracket plates require high structural strength, corrosion resistance, and precise dimensional a

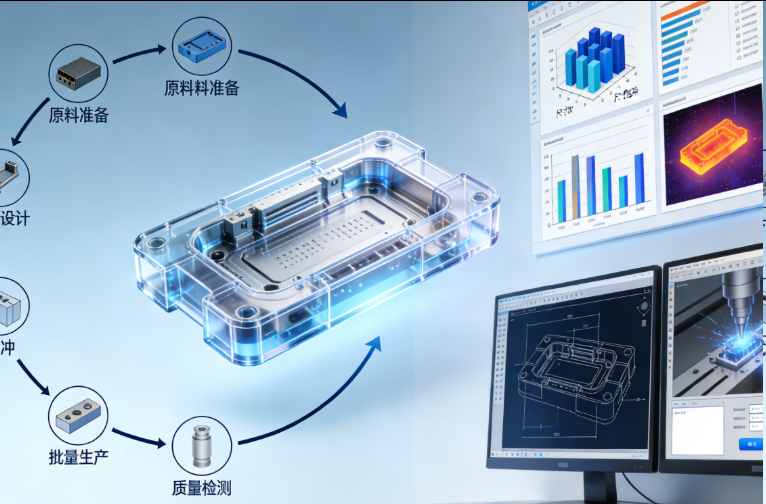

CNC (Computer Numerical Control) machining processes represent a cornerstone of modern precision manufacturing, utilizing computer-controlled systems to automate machine tool operations. The process begins with creating a 3D CAD model of the desired part, which is then translated into G-code ins

Stamping part in-process inspection (IPI) is a critical quality control step conducted during the stamping production process—between raw material feeding and final product assembly—to identify defects early, prevent the spread of non-conforming parts, and ensure consistency in manufacturing. Unlike

Stamping part material procurement is a critical first step in ensuring the quality, cost-effectiveness, and reliability of stamping products—used in industries like automotive, electronics, and aerospace. This process requires careful planning, supplier evaluation, and material specification alignm

Stamping parts produced using a hydraulic press are precision-manufactured components widely used in automotive, aerospace, electronics, and appliance industries—thanks to the hydraulic press’s ability to deliver high, consistent force for shaping and forming metal sheets (e.g., steel, aluminum, cop

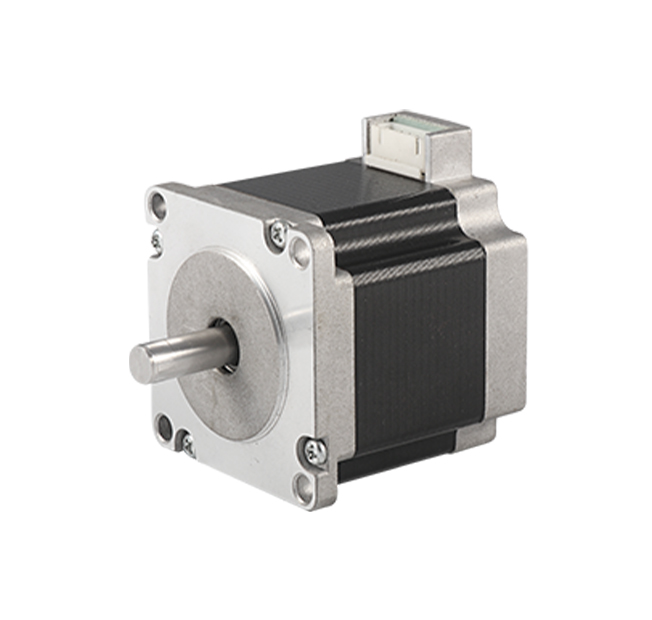

CNC Machining Robot Accessories encompass precision components used in robotic systems, such as robotic arm joints, end effectors (grippers), gearboxes, sensor mounts, and cable management brackets. These accessories are critical for ensuring robots’ mechanical stability, movement accuracy, and oper

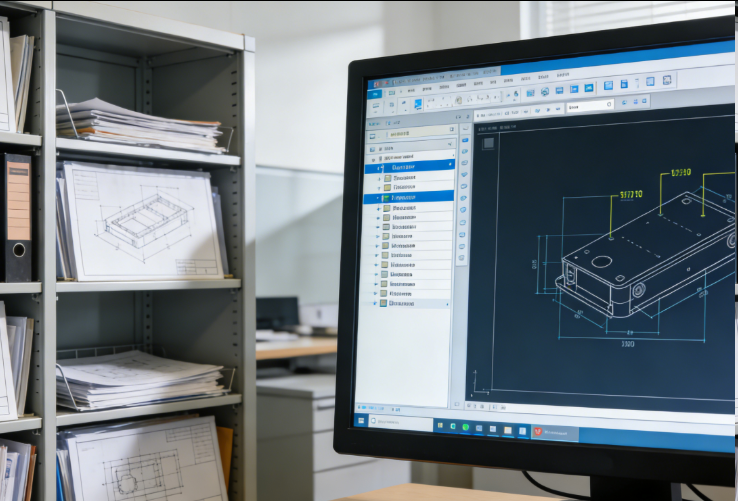

The integration of Computer-Aided Design (CAD) and Computer-Aided Manufacturing (CAM) is the digital backbone of modern stamped parts production, bridging the gap between theoretical product specifications and physical manufacturing reality. This symbiotic relationship ensures that stamped component

Green Manufacturing within the stamped metal parts industry involves a comprehensive strategy aimed at minimizing environmental impact throughout the entire product lifecycle, from raw material procurement and production processes to end-of-life recycling. Given that stamping is an energy-intensive

The efficient management of Engineering Change Orders (ECOs) for stamped parts is one of the most challenging and high-risk processes in discrete manufacturing, given the intrinsic link between product geometry and highly specialized, expensive tooling. Any change—whether driven by performance impro

CNC (Computer Numerical Control) machining equipment represents the pinnacle of modern manufacturing technology, integrating computer control with precision machining. These systems automate the operation of machine tools, such as lathes, mills, and grinders, through pre-programmed instructions. The

CNC precision machining is a manufacturing process that leverages computer-controlled systems to achieve extremely tight tolerances and high surface finishes. This method involves the removal of material from a workpiece using cutting tools, guided by precise digital instructions. The key advantage

Stamping part bending is a fundamental forming process that shapes flat metal sheets into angular or curved geometries—used to create components like brackets, hinges, and enclosures across industries such as automotive, electronics, and construction. This process relies on applying force to a metal

Stamping part process analysis is a comprehensive evaluation of the entire stamping workflow—from raw material preparation to finished part production—aimed at optimizing efficiency, reducing defects, and ensuring consistency. This analysis is not limited to individual steps (like bending or deep dr

A CNC hydraulic press for stamping parts is a high-precision, automated manufacturing machine designed to shape or form metal sheets into stamping components using hydraulic force and computer numerical control (CNC) technology. Unlike traditional manual or semi-automatic hydraulic presses, this equ

A turret punch press is a high-efficiency, automated stamping machine designed to produce large volumes of stamping parts with diverse hole patterns, cutouts, and shapes by leveraging a rotating turret (a cylindrical tool holder) equipped with multiple punches and dies. Unlike single-punch hydraulic

Material hardness is a critical mechanical property that defines a metal’s resistance to deformation, indentation, or wear during stamping operations—directly influencing the choice of stamping equipment, tool materials, and processing parameters. For stamping parts, hardness is typically measur

Tool selection is a critical step in sheet metal processing that directly impacts machining efficiency, part quality, tool life, and overall production costs. Sheet metal processing involves a range of operations such as cutting, punching, bending, and forming, each requiring specialized tools tailo

Sheet metal OEM processing is a specialized manufacturing service that focuses on customizing sheet metal components according to the specific design requirements, technical parameters, and brand standards of original equipment manufacturers (OEMs). Unlike standard sheet metal production, which

Precision stamping parts processing is a high-accuracy manufacturing technique that shapes metal materials into intricate, dimensionally consistent components using specialized stamping dies and high-pressure presses. Unlike conventional stamping (which focuses on basic shaping), precision stamping

Multi-layer stamping parts are specialized components composed of two or more stacked metal layers bonded or formed together through stamping processes, designed to combine the advantages of different materials (e.g., strength, conductivity, corrosion resistance) into a single, integrated part. Unli

CNC machining free prototyping is a customer-centric service offered by manufacturers to produce small-batch (usually 1-5 pieces) CNC-machined prototypes at no cost, allowing clients to verify design feasibility, test product performance, and validate quality before committing to mass production. Un

Sheet Metal Processing Technology encompasses a diverse set of specialized techniques designed to transform flat metal sheets into functional, three-dimensional components, integrating both subtractive (material removal) and formative (material shaping) methods to meet precision, strength, and aesth

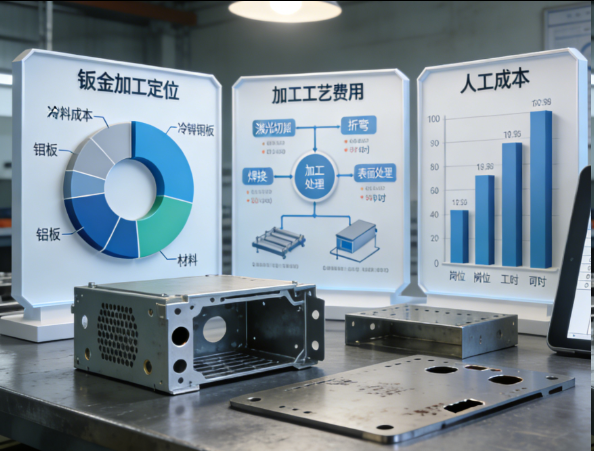

Sheet Metal Processing Pricing is a variable and project-specific cost determined by a combination of technical, material, and production-related factors, making it essential for clients to understand key cost drivers to budget effectively and optimize their designs for affordability. Unlike standar

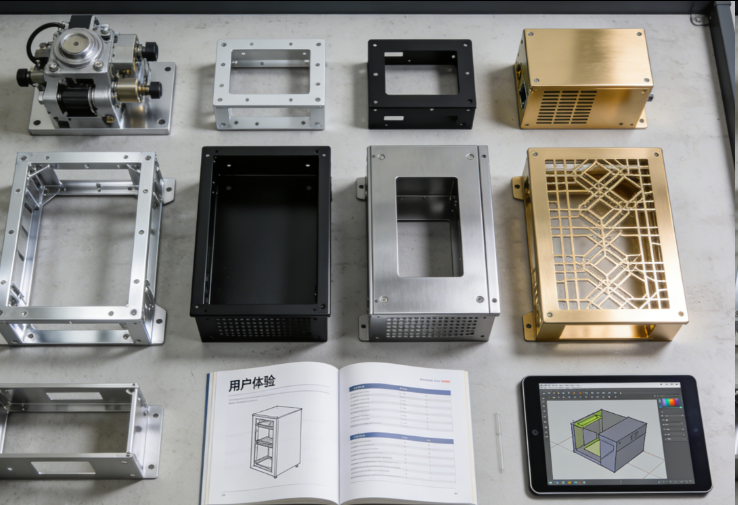

Sheet Metal Processing Factories are specialized manufacturing facilities dedicated to transforming flat metal sheets (e.g., aluminum, steel, stainless steel, brass) into functional, precision-engineered components or finished products through a series of subtractive and formative processes. These f

CNC Lathe Machining, also known as CNC turning, is a precision manufacturing process designed for producing cylindrical or rotationally symmetric parts by rotating the workpiece against a stationary cutting tool. Controlled by computer numerical programs, this method excels at creating features like

CNC (Computer Numerical Control) Machining Centers are advanced, automated manufacturing systems designed for high-precision, multi-tasking metal and non-metal processing. Unlike single-function machine tools (e.g., standalone lathes or mills), these centers integrate multiple operations—such as mil

Robotic arm feeding systems have become a cornerstone of modern stamping production, enabling precise, high-speed material handling for stamping parts across industries like automotive, electronics, and hardware. Unlike manual feeding (which is slow, error-prone, and risky for workers), robotic arms

Stamping mold design is a critical engineering process that directly determines the quality, precision, and production efficiency of stamping parts, serving as the core of stamping manufacturing for industries like automotive, electronics, and aerospace. A well-designed stamping mold ensures sta

Stamping parts with specialized coatings are engineered to enhance durability, corrosion resistance, and functional performance, making them indispensable for industries like automotive, aerospace, and electronics. Uncoated stamping parts (typically made of steel, aluminum, or copper alloys) are pro

Material hardness is a critical factor in stamping part production, as it directly influences processability, part performance, and tool lifespan—making careful material selection essential for meeting design requirements and manufacturing efficiency. Hardness refers to a material’s resistance to de

Stamping parts produced via turret punch press automation represent a high-efficiency, precision-focused manufacturing solution, widely adopted in industries like electronics, automotive, and sheet metal fabrication. A turret punch press is equipped with a rotating turret (a cylindrical tool hol

Automobile chassis components are the foundation of a vehicle's structural integrity and performance, and stamping parts play an indispensable role in their fabrication. The chassis, which supports the vehicle's body and houses critical systems such as the suspension, steering, and braking syste

In the marine industry, where components are constantly exposed to harsh environmental conditions such as saltwater corrosion, strong winds, and heavy waves, stamping parts for metal components play a crucial role in ensuring the durability, safety, and functionality of ships and other marine ve

Stamping parts play a pivotal role in the fabrication of cabinet metal components, offering a combination of strength, precision, and cost - effectiveness that is essential for modern industrial and commercial applications. Cabinets, whether used for electrical enclosures, data storage, or indus

Special - shaped stamping parts represent a significant category within the stamping industry, catering to the growing demand for components with unique and complex geometries. Unlike standard stamping parts, which typically have simple and regular shapes, special - shaped stamping parts are desig

CNC (Computer Numerical Control) machining, a cornerstone of modern manufacturing, has witnessed an increasing emphasis on environmental compliance in recent years. As industries worldwide strive to reduce their ecological footprint, adhering to environmental regulations and standards in CNC mac

In the highly competitive landscape of modern manufacturing, the integration of stamping parts into rapid assembly lines has revolutionized production efficiency and throughput. Stamping parts, which are manufactured through the process of shaping metal sheets using dies and presses, play a crucia

CNC machining material testing is a fundamental and meticulous process aimed at evaluating the properties, characteristics, and suitability of materials used in CNC machining operations. This testing is crucial as the performance and quality of the final machined parts are highly dependent on the ma

CNC (Computer Numerical Control) machining with six - axis linkage represents a significant leap forward in the realm of precision manufacturing, enabling the production of highly complex and intricate parts with unparalleled accuracy. Unlike traditional machining methods or lower - axis CNC systems

CNC machining of decorative finishing parts, often referred to as CNC machining of “optical finishing parts” in Chinese, represents a specialized and intricate application within the manufacturing realm. These parts, typically used in industries such as automotive, consumer electronics, and luxury g

CNC machining dimension accuracy is a fundamental aspect that significantly influences the functionality and interchangeability of machined parts. Achieving high - precision dimensions is crucial, especially in industries such as aerospace, automotive, and medical device manufacturing, where even th

Customized CNC (Computer Numerical Control) machining of aluminum parts has become a highly sought - after service in various industries due to the unique properties of aluminum and the precision capabilities of CNC technology. Aluminum is a lightweight, corrosion - resistant, and highly malleable m

Sheet metal spot welding is a widely used resistance welding process that joins two or more metal sheets by applying pressure and electric current to specific points. This method is particularly popular in industries such as automotive, aerospace, and appliance manufacturing due to its speed, effici

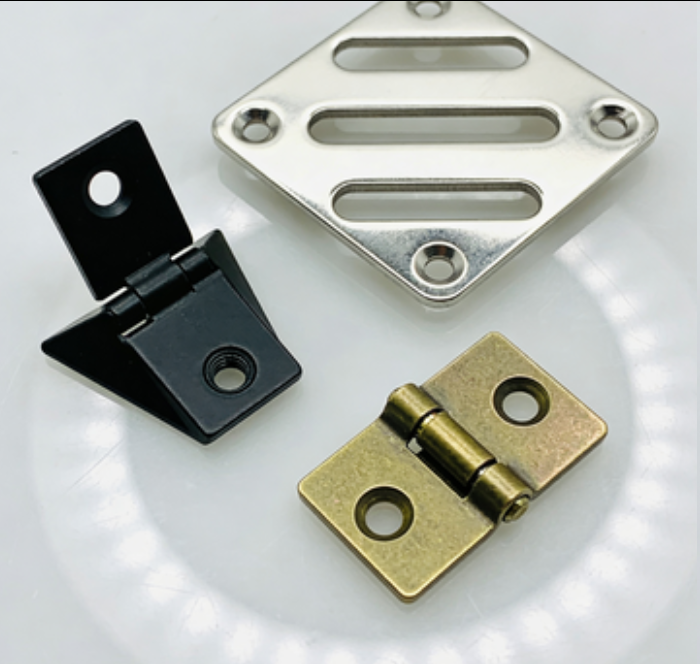

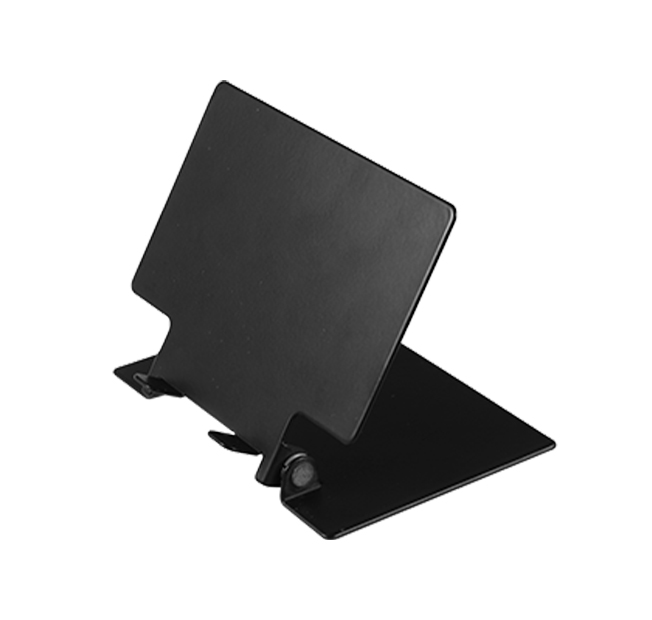

Sheet metal furniture accessories are integral components that enhance the functionality, durability, and aesthetic appeal of modern furniture. These precision-engineered parts, crafted from materials like steel, aluminum, and galvanized iron, serve diverse roles—from structural supports to decorati

Controlling stress deformation in stamped parts is crucial for ensuring dimensional accuracy and structural integrity in manufacturing processes. Stress deformation often arises from uneven material flow, residual stresses, and inconsistent contact between the workpiece and die during stamping opera

CNC (Computer Numerical Control) machining has emerged as an indispensable technology in the production of aerospace parts, where precision, reliability, and lightweight design are of utmost importance. The aerospace industry demands components that can withstand extreme conditions, including high a

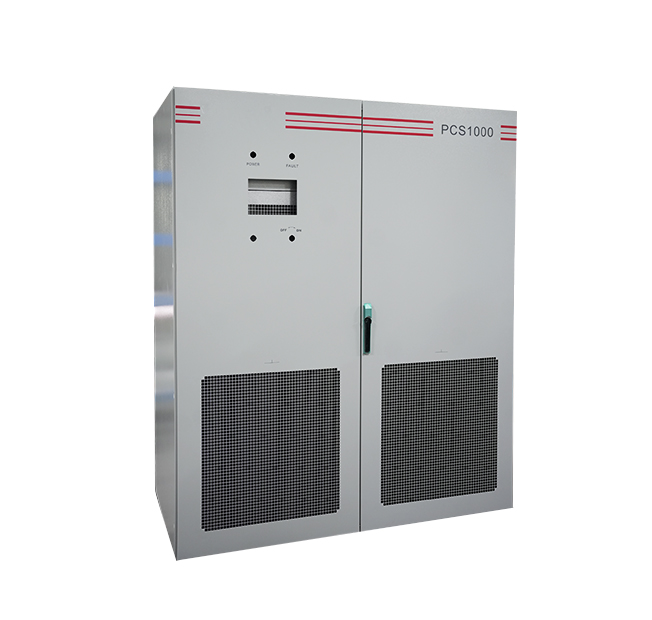

In the rapidly evolving landscape of the telecommunications industry, where seamless connectivity and reliable equipment are crucial, CNC machining has become an indispensable technique for manufacturing communication chassis. These chassis serve as the protective and functional framework for housin

Sheet metal parts with high - temperature resistance play a pivotal role in numerous industrial applications where exposure to elevated temperatures is inevitable. These parts are engineered to maintain their structural integrity, mechanical properties, and functionality under extreme heat condition

Injection molds for plastic automotive parts are of utmost importance in the automotive industry as they contribute to the production of components that are lightweight, durable, and cost - effective while meeting strict safety and performance requirements.One of the key plastic automotive parts mad

Injection molds for plastic food containers are essential in the production of safe and hygienic packaging for food products. These molds are designed to meet the specific requirements of the food industry, ensuring durability, functionality, and compliance with food safety regulations.The design pr

Injection molds for plastic construction materials are essential in the construction industry as they enable the production of components that offer several advantages over traditional materials, including durability, cost - effectiveness, and ease of installation.One of the key plastic construction

Injection molds for plastic automotive interior parts are essential for the production of modern and comfortable vehicles. As the automotive industry continues to focus on improving the interior design and functionality of cars, injection molding has become a key manufacturing method.The design of i

CNC machining with silver and nickel plating combines the precision of computer - numerical - controlled machining with the enhanced properties provided by these plating processes. CNC machining ensures high - accuracy shaping of components, while silver and nickel plating endows the machined parts

Sheet metal instrument panels serve as the interface between operators and various industrial, laboratory, or automotive instruments, playing a crucial role in functionality, usability, and aesthetics. The utilization of sheet metal for these panels is attributed to its remarkable properties, such a

Sheet metal trash can accessories play a vital role in enhancing the functionality, durability, and aesthetic appeal of trash cans. Sheet metal, with its strength, versatility, and cost - effectiveness, is an ideal material for manufacturing these accessories, which are essential components for both

Sheet metal display cabinet parts processing involves a series of sophisticated techniques and processes aimed at creating high - quality, durable, and aesthetically pleasing components for display cabinets. Sheet metal, a versatile material known for its strength, malleability, and relatively low c

Sheet metal drawing document management is a critical and systematic process that plays a pivotal role in the entire sheet metal manufacturing lifecycle. In modern manufacturing industries, where precision and efficiency are paramount, effective management of sheet metal drawing documents ensures se

The Sheet Metal Bill of Materials (BOM) list is a crucial document in the sheet metal manufacturing process. It serves as a comprehensive inventory that details all the raw materials, components, and sub - assemblies required to fabricate a sheet metal product. A well - structured BOM list is essent

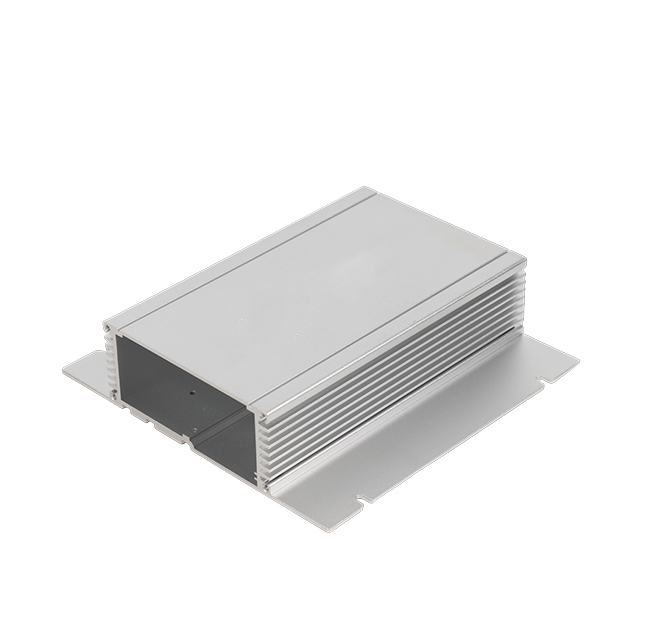

Sheet metal instrument enclosures are crucial protective casings for a wide range of instruments, providing both physical protection and functional support. These enclosures are designed to safeguard delicate internal components from external factors such as dust, moisture, impacts, and electromagne

CNC machining has revolutionized the production of industrial accessories, providing manufacturers with the ability to create highly precise, durable, and customized components. Industrial accessories encompass a wide range of parts, including fasteners, gears, couplings, and brackets, which are ess

Sheet metal precision structural components are at the forefront of modern manufacturing, providing high - accuracy and reliable structural support for a wide array of industries. These components are characterized by their meticulous design, precise manufacturing processes, and tight tolerances, wh

Sheet metal deep drawing is a specialized metal forming process that transforms flat sheet metal into complex, three-dimensional parts with deep cavities—such as cylindrical cans, automotive fuel tanks, kitchen sinks, and electronic enclosures. Unlike simple bending, which only changes the sheet’s a

Sheet metal nitrogen shielded welding is a specialized joining process widely utilized in the manufacturing industry, particularly for applications requiring high-quality, corrosion-resistant welds on thin-gauge sheet metal components. This technique leverages nitrogen gas as a shielding medium to d

Sheet metal power distribution boxes are essential components in electrical systems, providing secure housing for circuit breakers, switches, and wiring. The processing of these boxes involves a series of precision techniques to ensure durability, protection, and functionality.The process begins wit

Sheet metal machine tool guards are critical safety components designed to protect operators from moving parts, flying debris, and accidental contact with hazardous machinery. These guards, fabricated from durable sheet metal, are engineered to balance visibility, accessibility, and robust protectio

The Sheet Metal Conveyor Belt Frame is a robust, load-bearing structure that serves as the backbone of conveyor belt systems—essential equipment in manufacturing plants, warehouses, distribution centers, food processing facilities, and logistics hubs. Conveyor belts rely on this frame to support the

CNC machining combined with spray coating treatment offers a comprehensive solution for producing precision components with enhanced surface protection and aesthetic appeal. This process involves first using computer numerical control (CNC) machines to shape raw materials—such as metals, plastics, o

Surface polishing is a critical post-processing step for stamped parts, aimed at improving surface smoothness, enhancing aesthetic appeal, and reducing friction or wear in functional applications. Stamped parts, produced through processes like blanking, bending, or deep drawing, often have surface i

Sheet metal supermarket shelves are widely recognized for their durability, versatility, and cost-effectiveness, making them a staple in retail environments worldwide. Constructed from high-quality sheet metal—typically galvanized steel or stainless steel—these shelves offer exceptional strength to

Sheet metal air conditioner enclosures are critical structural and protective components in both residential and commercial air conditioning systems, designed to safeguard internal mechanical and electrical parts—such as compressors, condensers, and control boards—while ensuring efficient heat dissi

Power equipment—including switchgear, transformers, distribution cabinets, and renewable energy inverters—relies heavily on sheet metal components to ensure structural integrity, electrical safety, and long-term durability in harsh operating environments. These components, typically made from corros

Sheet metal automatic welding represents a significant advancement in manufacturing, leveraging robotic systems and advanced technologies to streamline the welding process for sheet metal components. This automated approach eliminates the variability associated with manual welding, ensuring consiste

Sheet metal equipment maintenance is a vital practice to ensure the longevity, efficiency, and safety of machinery used in sheet metal fabrication, such as laser cutters, press brakes, shears, and stamping presses. Regular maintenance not only prevents unexpected breakdowns that can disrupt producti

Laser cutting sheet metal blanking is a precision manufacturing process that uses a high-powered laser beam to cut flat sheet metal into specific shapes and sizes, serving as the initial step in many sheet metal fabrication workflows. This technology has revolutionized the industry by offering unpar

A sheet metal CNC machining center is an advanced automated manufacturing system designed specifically for precision processing of sheet metal materials, such as steel, aluminum, copper, and their alloys. Equipped with computer numerical control (CNC) technology, this versatile machine integrates mu

Sheet metal deformation compensation is a critical technique in metal fabrication, aimed at mitigating the inevitable shape changes that occur during processes like cutting, bending, welding, and stamping. These deformations, caused by residual stresses, thermal expansion, and material properties, c

Custom sheet metal fabrication is a versatile manufacturing process that involves transforming raw sheet metal into tailored components and structures based on specific design requirements. This highly adaptable service caters to a wide range of industries, including automotive, aerospace, electroni

Customized sheet metal products play a pivotal role in meeting the unique needs of various industries, from automotive and aerospace to electronics and construction. This service involves tailoring sheet metal components to specific dimensions, shapes, and functional requirements, ensuring they seam

CNC machining tool path planning is a critical step that directly impacts machining efficiency, tool life, and surface quality of the workpiece. Optimizing the tool path can significantly reduce production time, minimize tool wear, and enhance the overall precision of the machined parts. Here are se

Sheet metal electroplating treatment is a widely used surface finishing process that involves depositing a thin layer of metal onto the surface of sheet metal components through an electrochemical reaction. This technique not only enhances the aesthetic appeal of the sheet metal but also provides a

CNC machining has become an indispensable process in the production of consumer electronics enclosures, offering precision, versatility, and efficiency that meet the stringent requirements of modern devices. Consumer electronics such as smartphones, tablets, laptops, and smartwatches demand enclosur

The CNC machining process for solar equipment brackets is a precision-driven workflow designed to produce durable, weather-resistant structural components that secure solar panels in various installations, from residential rooftops to large-scale solar farms. These brackets, typically made from alum

The digital design process of stamping parts has undergone significant transformation with the advancement of computer - aided design (CAD) and computer - aided engineering (CAE) technologies. Optimizing this process is crucial for improving product quality, reducing development cycles, and lowering

Sheet metal surface treatment is a critical step in manufacturing, serving both functional and aesthetic purposes. Its primary goals include enhancing corrosion resistance, improving adhesion for subsequent coatings, and achieving a desired surface finish. Various techniques are employed based on th

Dimensional accuracy is a cornerstone of CNC machining quality, directly influencing the functionality and assembly of mechanical parts. Achieving precise dimensional control requires a systematic approach integrating equipment calibration, process optimization, and real-time monitoring.Firstly, mac

CNC precision machining centers rely on sophisticated programming methods to translate design specifications into precise manufacturing operations. The primary programming approaches include manual G-code programming, computer-aided manufacturing (CAM) software programming, and conversational progra

The deep integration of stamping part processing and intelligent manufacturing is reshaping traditional production paradigms by leveraging advanced technologies such as automation, data analytics, and artificial intelligence. At the core of this integration is the implementation of smart production

CNC machining of precision aluminum alloy parts is a highly accurate manufacturing process that leverages computer numerical control (CNC) systems to produce complex components with tight tolerances, often as low as ±0.001 mm. Aluminum alloys, such as 6061, 7075, and 5052, are preferred for their ex

5-axis machining plays a pivotal role in the medical equipment industry, where precision, complexity, and biocompatibility are paramount. This advanced manufacturing technique enables the production of intricate components that are critical to diagnostic, surgical, and therapeutic devices. One key

The integration of CNC (Computer Numerical Control) machining and 3D printing represents a groundbreaking synergy in modern manufacturing, combining the precision of subtractive manufacturing with the design freedom of additive manufacturing. This hybrid approach addresses the limitations of each te

In the realm of electrical engineering, the customization of sheet metal power distribution boxes is a critical process that caters to the diverse and specific requirements of different power systems. These boxes serve as the nerve centers for power distribution, ensuring the safe and efficient tran

The integration of sheet metal processing with the Industrial Internet (IIoT) is transforming traditional manufacturing into a data-driven, intelligent ecosystem, enhancing efficiency, precision, and responsiveness. At its core, this connection involves embedding sensors, IoT-enabled devices, and co

The sheet metal riveting process is a widely - used joining method in various industries due to its simplicity, reliability, and adaptability. It involves fastening two or more sheet metal components together using rivets, which can be made of different materials such as aluminum, steel, or copper.

Special machining methods in CNC (Computer Numerical Control) machining refer to non-traditional techniques that remove material through processes other than conventional cutting, grinding, or drilling. These methods are critical for processing materials with extreme hardness, brittleness, or co

In the field of CNC machining, surface coating technology has undergone significant innovations to enhance the performance, durability, and functionality of machined components. Traditional coatings like chrome plating and anodizing are being replaced or augmented by advanced solutions that offe

Copper alloys, known for their excellent electrical conductivity, thermal conductivity, and machinability, require specific techniques to ensure precision and efficiency in CNC machining. One key tip is tool selection. Carbide tools are preferred over high-speed steel due to their superior wear

The combination of sheet metal processing and non-metallic sheets has opened up new possibilities in various industries, offering a blend of the mechanical strength of metals and the unique properties of non-metallic materials. One common method of combining these materials is through adhesive b

CNC (Computer Numerical Control) machining has revolutionized the manufacturing of heat sink fins for lighting fixtures, providing high - precision, efficient, and customized solutions. Heat sink fins play a crucial role in lighting fixtures, especially for high - power LED lights, as they help

Stress deformation during CNC machining can significantly affect the dimensional accuracy and surface quality of workpieces, leading to product failures. To control stress deformation, several effective methods can be employed. Firstly, The selection of cutting parameters has a profound impact

Hot-rolled sheets play a crucial role in sheet metal processing, finding extensive applications across various industries due to their unique properties and cost-effectiveness. These sheets are produced by rolling steel at high temperatures, above its recrystallization point, which results in go

Ensuring the geometric tolerances of stamping parts is necessary to guarantee proper fit, function, and performance when assembled with other components. A series of measures are implemented in the stamping process to maintain strict geometric tolerances. Firstly, proper die alignment and insta

Controlling the dimensional accuracy of stamping parts is essential to ensure proper assembly and functionality in various products. Several key technologies are employed in the stamping process to achieve high-dimensional accuracy. Die design and manufacturing play a crucial role. Advanced com

Accurate detection of the surface flatness of stamping parts is vital to ensure their quality and compatibility with other components. There are several methods available for surface flatness detection, each with its own advantages and suitable applications. One of the most common methods is th

Controlling the surface roughness of stamping parts is crucial as it directly impacts the functionality, aesthetics, and service life of the final product. Surface roughness can affect the fit between components, the performance of mating parts, and the overall appearance of the stamping part, e

High-strength steel (HSS) has become an increasingly popular material choice in sheet metal processing, especially in industries where strength, durability, and weight reduction are critical factors. HSS offers higher yield and tensile strengths compared to conventional mild steel, allowing for

The integration of composites in sheet metal processing has revolutionized the manufacturing industry, providing enhanced performance characteristics compared to traditional metallic materials. Composites, typically consisting of a matrix material (such as polymers) reinforced with fibers (like

Sheet metal processing encompasses a wide range of special processing methods that go beyond traditional techniques, offering unique capabilities for complex and specialized applications. These methods are designed to handle challenging materials, create intricate geometries, or achieve specific

Ultra-precision machining in sheet metal processing has emerged as a critical technology in modern manufacturing, catering to industries with stringent requirements for dimensional accuracy, surface finish, and form tolerance. In contrast to traditional sheet metal processing, which may tolerate

Cold - rolled sheets are widely used in sheet metal processing, especially in stamping operations, due to their excellent dimensional accuracy, smooth surface finish, and consistent mechanical properties. The stamping performance of cold - rolled sheets is influenced by several factors related t

Surface treatment of galvanized steel sheets is of utmost importance in sheet metal processing as it significantly affects the performance, durability, and appearance of the final products. Galvanized steel sheets are coated with a layer of zinc, which provides excellent corrosion protection. Ho

Stainless steel sheets present several challenges during sheet metal processing due to their unique material properties. One of the primary difficulties is related to their high strength and hardness. Stainless steel, especially types like 304 and 316, has a relatively high yield strength and ul

Aluminum alloy materials are widely utilized in sheet metal processing due to their unique combination of properties that make them highly suitable for a diverse range of applications. The fundamental characteristic of aluminum alloys lies in their low density, which is approximately one - third

Springback is a phenomenon that occurs when sheet metal elastically recovers its shape after the removal of the forming forces during bending or stamping operations. It can cause significant dimensional inaccuracies, making it difficult to meet the required specifications of the sheet metal part

Stress deformation is a common challenge in sheet metal processing, which can occur due to various factors such as uneven material removal, thermal effects during machining, and internal residual stresses. Excessive stress deformation can lead to dimensional inaccuracies, poor product performanc

Ensuring the surface flatness of sheet metal components is vital for their proper assembly and functionality in various applications. Deviations from flatness can cause problems such as poor fit - up during assembly, increased stress concentrations, and reduced structural integrity. Therefore, a

Surface roughness is a critical parameter in sheet metal processing, significantly influencing the functionality, aesthetics, and durability of the final product. In sheet metal manufacturing, a rough surface can lead to increased friction, reduced corrosion resistance, and poor adhesion of coat

Cold work hardening, also known as strain hardening, is a crucial process in sheet metal processing that significantly enhances the mechanical properties of metal sheets. This treatment involves deforming the metal at temperatures below its recrystallization point, typically at room temperature,

Hot processing in sheet metal manufacturing encompasses a range of techniques performed at elevated temperatures, where the metal becomes more malleable and easier to shape. These techniques, including hot rolling, hot forging, and hot stamping, often need to be coordinated effectively to achiev

Hot processing in sheet metal manufacturing encompasses a range of techniques performed at elevated temperatures, where the metal becomes more malleable and easier to shape. These techniques, including hot rolling, hot forging, and hot stamping, often need to be coordinated effectively to achiev

On - line detection technology in sheet metal processing plays a vital role in ensuring product quality, improving production efficiency, and reducing waste. This technology enables real - time monitoring and inspection of sheet metal parts during the manufacturing process, allowing for immediat

Non - destructive testing (NDT) methods are essential in sheet metal processing as they allow for the evaluation of the integrity and quality of sheet metal parts without causing any damage to the components. These methods are crucial for detecting internal defects, material inhomogeneities, and oth

In the modern era, elevators are not just a means of vertical transportation but also a symbol of technological advancement and safety. The precision and reliability of elevator components, particularly the carriage, are crucial for ensuring smooth operation and passenger safety. CNC (Computer N

The manufacturing of metal frames for logistics equipment is a critical process that requires high precision and durability to ensure the efficient and safe transportation of goods. CNC (Computer Numerical Control) technology plays a pivotal role in this process, enabling the production of compl

Sealing design is a critical aspect of packaging machinery, as it ensures the integrity and functionality of the equipment while preventing leaks and contamination. CNC (Computer Numerical Control) technology plays a vital role in the precision manufacturing of components for packaging machinery

The toy industry is subject to stringent safety standards to ensure that products are safe for children to use. CNC (Computer Numerical Control) technology plays a crucial role in the precision manufacturing of plastic molds for toys, ensuring that the final products meet these rigorous requirem

In the realm of bathware hardware, corrosion resistance is a critical factor that ensures longevity and aesthetic appeal. CNC (Computer Numerical Control) technology plays a pivotal role in manufacturing high-precision components for bathroom fixtures such as faucets, showerheads, and towel bars

Automated control technologies play a pivotal role in modern sheet metal processing, enabling precise and efficient operations. One of the fundamental control technologies is the use of computer - numerical control (CNC). In sheet metal processing, CNC systems are used to control various machine

Selecting the right automated equipment for sheet metal processing is a decision - making process that involves evaluating multiple factors to meet the specific requirements of the production. One of the primary considerations is the type of sheet metal processing operations. For cutting operati

The design of an automated production line for sheet metal processing is a complex and systematic process that requires careful consideration of various factors. First and foremost, the layout of the production line is crucial. The line should be designed in a way that maximizes the flow of mate

The design of an automated production line for sheet metal processing is a complex and systematic process that requires careful consideration of various factors. First and foremost, the layout of the production line is crucial. The line should be designed in a way that maximizes the flow of mate

Destructive testing in sheet metal processing is essential to ensure the quality and integrity of the fabricated components. These standards are established based on a combination of industry best practices, safety requirements, and material properties. One of the primary aspects of destructive

Hot-Chamber Die Casting: Used for low-melting-point metals like zinc and tin. The melting pot is integrated into the machine, and a piston injects metal directly into the die, enabling faster cycle times (20–60 seconds per part). Cold-Chamber Die Casting: Suitable for high-melting-point metals

Injection molds can be made from steel or aluminum. Aluminum molds are cheaper (suitable for low-volume production) but less durable, while steel molds (e.g., P20, H13 steel) are costlier but ideal for high-volume runs. The cost of a steel injection mold depends on part complexity, cavity count

Die casting and injection molding are two distinct manufacturing processes with unique characteristics, applications, and material requirements. Die Casting Die casting involves forcing molten metal under high pressure into a reusable mold, known as a die. This process is typically used for no

Plastic mold machining is a subtractive manufacturing process that involves using CNC machines (e.g., milling machines, lathes, EDM machines) to remove material from a solid block (typically steel or aluminum) to create the mold’s cavity and core. This stage focuses on precision and surface fini

When it comes to CNC machining of food - contact components for food machinery, strict safety and hygiene standards must be adhered to, in addition to achieving high - precision dimensions. The choice of materials is of utmost importance, with food - grade stainless steels (such as 304 and 316)

CNC manufacturing of aseptic components for pharmaceutical equipment demands the highest levels of precision, cleanliness, and sterility. These components are integral to maintaining the integrity of pharmaceutical production processes, ensuring the safety and efficacy of drugs. The selection o

Environmental protection equipment often operates in harsh environments where components are exposed to various corrosive substances, such as acids and alkalis. CNC machining of acid - and alkali - resistant components focuses on material selection, machining precision, and surface treatment to

CNC (Computer Numerical Control) drum machining technology plays a pivotal role in the manufacturing of high - performance printing equipment. Printing drums are key components that directly impact the quality and efficiency of the printing process, and precise CNC machining is essential to meet

Cost accounting in stamping parts processing is a crucial process that helps manufacturers accurately determine the expenses involved in producing stamping parts, enabling them to price their products competitively and manage profitability effectively. The cost of stamping parts processing can b

The stamping parts processing industry is highly competitive, influenced by various factors such as market demand, technological advancements, and the entry of new players. Understanding the competitive landscape is essential for companies to formulate effective strategies and maintain their com

The stamping parts processing industry is constantly evolving, and new application fields are emerging, driven by technological advancements and changing market demands. These emerging areas present new opportunities for manufacturers to expand their business and increase their market share. On

The integration of stamping parts processing and 3D printing technologies offers new possibilities for manufacturing, combining the advantages of both methods to create more innovative and efficient solutions. Stamping is a high - volume, cost - effective manufacturing process suitable for prod

The layout design of a sheet metal processing workshop has a significant impact on production efficiency, safety, and workflow. First, the layout should consider the processing sequence. Arrange the equipment in the order of the processing flow, starting from material storage, cutting, bending,

Ensuring safety in sheet metal processing requires strict adherence to operating procedures. Before starting any processing operation, operators must conduct a thorough inspection of the equipment. Check for any signs of damage, loose parts, or abnormal electrical connections. For example, when

The cultivation of sheet metal processing talents is crucial for the development of the sheet metal industry. One of the primary approaches is through vocational education and training institutions. These institutions offer specialized courses covering theoretical knowledge, such as metal materi

In sheet metal processing, various defects may occur during different stages of production, and effective repair methods are essential to ensure product quality. One common defect is surface scratches. For minor scratches, polishing techniques can be employed. Using abrasive papers with differen

CNC wood processing technology has revolutionized the production of office furniture, enabling the creation of precise, high - quality, and customized wooden components. This technology encompasses several key processes and considerations to ensure the best results in terms of functionality, aes

The CNC machining of metal structural components for communication base stations is a complex process that requires a focus on strength, precision, and environmental adaptability to ensure the reliable operation of the base stations in various outdoor environments. Material Selection for Streng

Key Points of CNC Plastic Parts Processing for Home Appliances CNC plastic parts processing for home appliances has its own unique set of key points that need to be considered to produce high - quality, functional, and aesthetically pleasing components. These points involve aspects such as materi

The manufacturing of CNC components for medical devices is subject to extremely stringent requirements due to the critical nature of these products, which directly impact patient safety and treatment effectiveness. Every aspect of the manufacturing process, from material selection to quality con

Sheet metal equipment enclosures play a vital role in mechanical manufacturing by protecting the internal machinery and equipment from external factors while also providing ease of access for operation and maintenance. One of the key considerations in the design and fabrication of these enclosur

The installation of sheet metal curtain walls for architectural decoration is a complex process that requires careful planning and execution to achieve both aesthetic and functional goals. The first step is the preparation of the construction site. This includes ensuring that the building struct

The installation of sheet metal curtain walls for architectural decoration is a complex process that requires careful planning and execution to achieve both aesthetic and functional goals. The first step is the preparation of the construction site. This includes ensuring that the building struct

Sheet metal structural components in the aerospace industry possess unique characteristics that are essential for meeting the stringent requirements of aircraft and spacecraft. High strength - to - weight ratio is a fundamental characteristic. Materials such as aluminum - lithium alloys are wide

The selection of materials for sheet metal cabinets in communication base stations is a critical decision, as these cabinets house essential communication equipment and need to ensure reliable operation in diverse environmental conditions. One of the most commonly used materials is cold - rolled

The CNC shell processing flow for electronic equipment involves several sequential steps to produce high - quality, functional, and aesthetically pleasing enclosures. The process begins with design and programming. Engineers use computer - aided design (CAD) software to create detailed 3D models

CNC precision processing technology is of utmost importance in the aerospace industry, where parts need to meet extremely high standards of accuracy, reliability, and performance. One of the key technologies is high - speed machining (HSM). HSM allows for the rapid removal of material while main

Customizing CNC processing technology for automobile parts is essential to meet the diverse and high - performance requirements of the automotive industry. Each type of automobile part, from engine components to chassis parts, has unique design and functional needs that demand tailored machining

Reducing CNC processing costs is a critical concern for manufacturers aiming to enhance competitiveness and profitability. One of the primary ways to cut costs is through optimized material utilization. By carefully analyzing the design of the parts to be processed, manufacturers can minimize ma

Ensuring the quality of sheet metal welding is vital to guarantee the structural integrity and performance of sheet metal products. There are several established quality inspection standards that cover various aspects of sheet metal welding. Visual inspection is the most basic and initial metho

Sheet metal laser cutting equipment operates based on several key parameters that significantly impact the cutting quality, speed, and efficiency. The first and most critical parameter is the laser power. Laser power determines the energy available to melt and vaporize the sheet metal. Higher -

Calculating the sheet metal bending angle accurately is essential for achieving the desired shape and dimensional accuracy in sheet metal fabrication. One of the fundamental methods is based on the neutral axis concept. When sheet metal is bent, the inner side of the bend is compressed, and the

Sheet metal processing is a complex and multi - step procedure that demands meticulous attention to detail at every stage. The initial step often involves material selection. Commonly used materials include stainless steel, aluminum, and cold - rolled steel. Each material has distinct properties

The stamping parts processing industry requires a diverse range of talents, including skilled technicians, engineers, and managers. Developing effective talent cultivation approaches is essential for the industry's sustainable development. Vocational education and training institutions play a v

The stamping parts processing supply chain involves multiple stakeholders, from raw material suppliers to end - product manufacturers. Optimizing this supply chain is essential for improving efficiency, reducing costs, and enhancing competitiveness. One key strategy is to strengthen supplier re

Stamping parts processing enterprises need effective management modes to enhance productivity, control costs, and ensure product quality. A comprehensive management approach typically encompasses aspects such as production management, quality management, equipment management, and personnel manag

Industry standards in stamping parts processing are crucial for ensuring product quality, safety, and compatibility across different applications. These standards cover a wide range of aspects, from material specifications to dimensional tolerances and surface finish requirements. Material - re

Regular maintenance and proper service of CNC equipment are essential for ensuring its reliable operation, extending its lifespan, and maintaining high - quality machining performance. Establishing appropriate maintenance cycles and implementing effective maintenance methods are crucial steps in

Maintaining high precision in CNC processing is vital for producing parts that meet strict dimensional and quality requirements. Several key technical points need to be focused on to ensure accurate and consistent machining results. Machine Tool Accuracy and Calibration The accuracy of the CNC

Optimizing the processing technology of CNC milling machines is essential for enhancing production efficiency, reducing costs, and improving the quality of machined parts. Several effective methods can be employed to achieve this goal, covering aspects from process planning to parameter adjustme

Selecting the appropriate tools for a CNC engraving machine is a crucial decision that directly impacts the quality, efficiency, and precision of the engraving process. Different engraving tasks, materials, and machine capabilities require specific types of tools. A comprehensive understanding o

Intelligent technologies are revolutionizing the sheet metal processing industry, bringing significant improvements in efficiency, quality, and flexibility. Artificial intelligence (AI) and machine learning (ML) are at the forefront of these technological advancements. AI - powered process opti

Automation has become a key strategy for improving efficiency, productivity, and quality in sheet metal processing. A comprehensive automated solution typically involves multiple aspects, from material handling to the final product output. Material handling automation is the starting point. Aut

The sheet metal processing industry is experiencing significant transformations driven by technological advancements, changing market demands, and global economic factors. One of the most prominent trends is the increasing demand for lightweight and high - strength sheet metal products. In indus

Ensuring the cleanliness of sheet metal equipment used in food packaging is of paramount importance for maintaining food safety and product quality. This cleaning process involves multiple steps and considerations to eliminate potential contaminants and prevent cross - contamination. First, pre

The production of surface textures on stamping parts serves multiple purposes, including enhancing aesthetics, improving functionality, and increasing surface adhesion. There are several methods available for creating different types of surface textures on stamping parts. One common method is m

Surface hardening treatment processes are essential for improving the wear resistance, fatigue strength, and overall durability of stamping parts. These processes focus on altering the surface properties of the part while maintaining the ductility and toughness of the core material. One widely

Surface coating technologies play a vital role in enhancing the performance, durability, and aesthetics of stamping parts. In recent years, there has been a surge in innovative coating techniques aimed at meeting the evolving demands of various industries. One of the emerging trends is the deve

Composite processing of non - metallic sheets for stamping parts combines multiple manufacturing techniques to create components with enhanced properties, improved functionality, and unique characteristics. This approach has become increasingly popular as industries seek to leverage the advantag

The stamping parts processing industry is constantly evolving, and exploring innovative ideas for processing technology is essential to keep up with market demands and improve competitiveness. These innovative ideas can cover various aspects, from new materials and processes to intelligent manuf

When stamping parts have defects, repair technology can be an effective way to save costs and reduce waste. Research on stamping parts processing defect repair technology focuses on developing and improving methods to restore the functionality and appearance of defective parts. One common defec

Stamping parts processing often encounters various quality problems that can affect the performance, functionality, and appearance of the final products. Analyzing these problems accurately and finding effective solutions is crucial for ensuring product quality and customer satisfaction. One co

In the stamping parts processing industry, controlling material loss is crucial for reducing production costs and improving economic efficiency. Material costs often account for a significant proportion of the total production cost, and even a small reduction in material loss can lead to substan

Micro - and nano - fabrication processes have opened up new frontiers in sheet metal processing, enabling the creation of ultra - precise components with dimensions at the micro and nanometer scales. These advanced techniques are crucial for industries such as microelectronics, micro - electrome

Additive manufacturing, also known as 3D printing, has brought revolutionary changes to the field of sheet metal processing. Traditionally, sheet metal fabrication relied on subtractive methods like cutting, bending, and stamping. However, additive manufacturing technologies offer new possibilit

When sheet metal processing equipment malfunctions, quick and accurate fault diagnosis is essential to minimize production interruptions. A systematic approach to troubleshooting can help identify the root cause of problems and implement effective solutions. The first step in fault diagnosis is

Maintaining sheet metal processing equipment is crucial for ensuring consistent product quality, maximizing operational efficiency, and extending the lifespan of the machinery. A well - maintained setup can reduce downtime, lower repair costs, and enhance overall productivity in a sheet metal fa

When purchasing stamping parts processing equipment, several important factors need to be considered to ensure that the equipment meets production requirements, is cost - effective, and has a long service life. Production Requirements Analysis The first step is to thoroughly analyze the produc

When stamping parts processing equipment malfunctions, quick and accurate troubleshooting is crucial to minimize production downtime and ensure continuous operation. Equipment - Specific Fault Diagnosis For mechanical presses, common faults may include problems with the clutch - brake system,

The layout of a stamping parts processing workshop has a significant impact on production efficiency, safety, and material flow. An optimized layout design aims to streamline operations, reduce production costs, and improve overall productivity. Workflow - Oriented Layout The first principle o

The design of a stamping parts processing training course should comprehensively cover theoretical knowledge, practical skills, and safety awareness to cultivate proficient stamping workers. Theoretical Foundation The course begins with an introduction to the basic principles of stamping. Trai

The selection and application of stamping parts processing tools are critical factors that directly impact the quality, efficiency, and cost of stamping production. Different types of stamping processes require specific tools, and choosing the right ones is essential. For blanking operations, p

When it comes to stamping parts expansion drawing, choosing the right software is crucial for ensuring accurate and efficient design. AutoCAD is a well - known and widely used software in the field of engineering drawing. It offers powerful 2D and 3D drawing capabilities, enabling designers to c

The flexible manufacturing system (FMS) for stamping parts processing offers numerous advantages that have revolutionized the traditional manufacturing approach. One of the most prominent benefits is its high adaptability. FMS can quickly respond to changes in production requirements, su

Mass production management of stamping parts processing is a complex yet essential task that encompasses multiple aspects, aiming to achieve high - efficiency, high - quality, and cost - effective production. One of the primary focuses is production planning and scheduling. In large - scale stam

The demand for small - batch customization in the stamping parts processing industry has been increasing due to the growing market for personalized products. To meet this demand, several innovative solutions have emerged. One approach is the use of flexible manufacturing systems (FMS). FMS combi

In response to the global call for environmental protection, the stamping parts processing industry is actively exploring and implementing green and environmentally friendly processes. One of the main areas of focus is energy conservation. Modern stamping equipment is being designed with energy

Designing an automated production line for stamping parts processing requires a comprehensive understanding of the stamping process, production requirements, and available automation technologies. The first step is to analyze the product range and production volume. Based on this analysis, a sui

The stamping parts processing industry is currently undergoing significant transformations driven by technological advancements, changing market demands, and global economic dynamics. One of the most prominent trends is the integration of advanced digital technologies. With the rise of the Inter

Ensuring the quality of sheet metal products is essential for customer satisfaction and the reputation of manufacturers. However, various quality problems can occur during the sheet metal processing, and a thorough analysis of these problems is necessary to find effective solutions. One common

Small - batch production in sheet metal processing has become increasingly important as the market demands more customized and diversified products. Unlike large - scale mass production, small - batch production requires flexible and efficient production modes to meet the unique requirements of

High - precision in sheet metal processing is critical for applications where exact dimensions, smooth surfaces, and tight tolerances are required, such as in the aerospace, automotive, and electronics industries. Achieving high precision involves a combination of advanced equipment, precise con

In an era where environmental protection has become a global priority, the adoption of green and environmentally friendly processes in sheet metal processing is not only a social responsibility but also a strategic choice for the sustainable development of the industry. These processes aim to mi

Quality inspection standards for stamping parts processing play a vital role in ensuring the quality and reliability of stamping parts. Understanding and correctly implementing these standards is essential for manufacturers to meet customer requirements and industry regulations. Dimensional acc

Controlling the cost of stamping parts processing is crucial for the competitiveness and profita

The optimization of stamping parts processing technology is essential for improving production e

The lifespan of stamping dies is a critical factor in the stamping parts manufacturing process,