Time:2025-12-25 Views:0 source:CNC Machining customization source:CNC Machining news

Stamping parts play a critical role in the manufacturing of display cabinet metal frames, serving as core structural components that ensure stability, durability, and aesthetic consistency for retail, exhibition, and home storage display cabinets. Unlike traditional welded or cast metal components (which may have inconsistent dimensions or weak load-bearing capacity), stamping parts are produced via precision metal stamping processes—using high-pressure presses and custom dies to shape flat metal sheets (typically aluminum, cold-rolled steel, or stainless steel) into standardized, complex shapes such as crossbars, vertical supports, corner brackets, and shelf rails. This process ensures tight dimensional tolerances (often within ±0.1mm), uniform thickness, and strong structural integrity, making them ideal for supporting the weight of displayed items (e.g., retail products, collectibles, or household goods) without bending or warping.

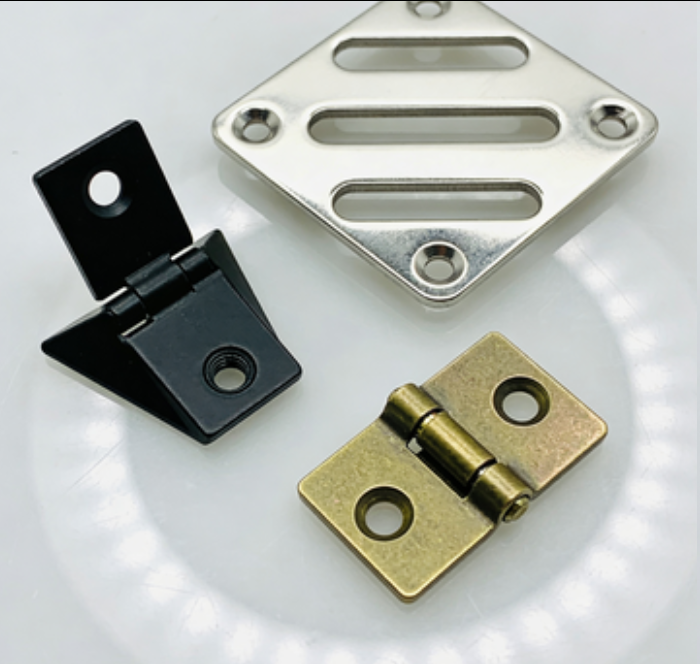

A key advantage of stamping parts for display cabinet frames is their versatility in design. Manufacturers can create custom dies to produce parts in various sizes, shapes, and finishes (e.g., powder-coated, galvanized, or brushed metal) to match different display cabinet styles—from sleek modern retail showcases to industrial-style home storage cabinets. For example, stamping-produced corner brackets feature pre-punched holes for easy assembly (reducing installation time), while stamped crossbars have reinforced edges to enhance load-bearing capacity (supporting up to 50kg per shelf for heavy products like electronics or glassware).

Durability is another standout feature: stamping parts are made from high-strength metals that resist corrosion (stainless steel) or wear (aluminum), ensuring the display cabinet frame maintains its structural stability for years—critical for high-traffic retail environments or long-term home use. Additionally, the mass-producibility of stamping processes lowers production costs compared to custom machining, making display cabinets more affordable for both businesses and consumers. Whether used in a shopping mall’s product showcase, a museum’s exhibit display, or a home’s kitchen storage cabinet, stamping parts for display cabinet metal frames deliver the precision, strength, and flexibility needed to create functional, long-lasting display solutions.

Read recommendations:

Sealing ring Precision electronic parts

Housing components for recessed downlights Precision electronic parts

Oval Magnetic Hardware Precision electronic parts