Time:2026-01-09 Views:0 source:CNC Machining customization source:CNC Machining news

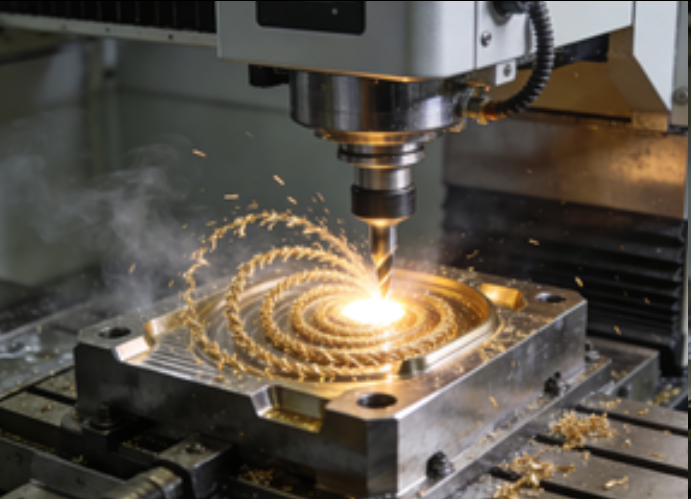

CNC machining high - speed milling represents a cutting - edge manufacturing technology that has revolutionized the production of complex components across various industries. This advanced machining process involves operating computer - numerically controlled (CNC) machines at elevated speeds to rapidly remove material and create intricate geometries with exceptional precision and surface finish.

At the heart of high - speed milling is the utilization of high - performance spindle motors capable of reaching extremely high rotational speeds, often ranging from 10,000 to 40,000 revolutions per minute. These powerful spindles, combined with specialized milling cutters designed for high - speed operations, enable rapid material removal rates while maintaining tight tolerances. The high - speed rotation of the cutter reduces the cutting forces and heat generated during the machining process, minimizing the risk of thermal distortion and improving the dimensional accuracy of the part.

CNC machining software plays a crucial role in high - speed milling. Sophisticated computer - aided design (CAD) and computer - aided manufacturing (CAM) programs are used to generate optimized toolpaths tailored specifically for high - speed cutting. These toolpaths take into account factors such as cutting speed, feed rate, and tool engagement to ensure efficient and safe machining. By precisely controlling the movement of the cutting tool, the software enables the creation of complex shapes, including free - form surfaces, deep cavities, and thin - walled structures that are challenging or impossible to achieve with conventional machining methods.

High - speed milling is widely applied in industries such as aerospace, automotive, mold and die making, and medical device manufacturing. In aerospace, it is used to produce lightweight yet strong components like turbine blades and structural parts, where precision and material removal efficiency are of utmost importance. In the automotive industry, high - speed milling helps in manufacturing engine components, transmission parts, and intricate molds for body panels. The ability to produce parts with excellent surface finish also reduces the need for secondary finishing operations, saving both time and cost in the production process. Overall, CNC machining high - speed milling offers a combination of speed, precision, and flexibility, making it an indispensable technology for modern manufacturing.

Read recommendations:

Sealing ring Precision electronic parts

Housing components for recessed downlights Precision electronic parts

Oval Magnetic Hardware Precision electronic parts