Time:2025-12-18 Views:0 source:CNC Machining customization source:CNC Machining news

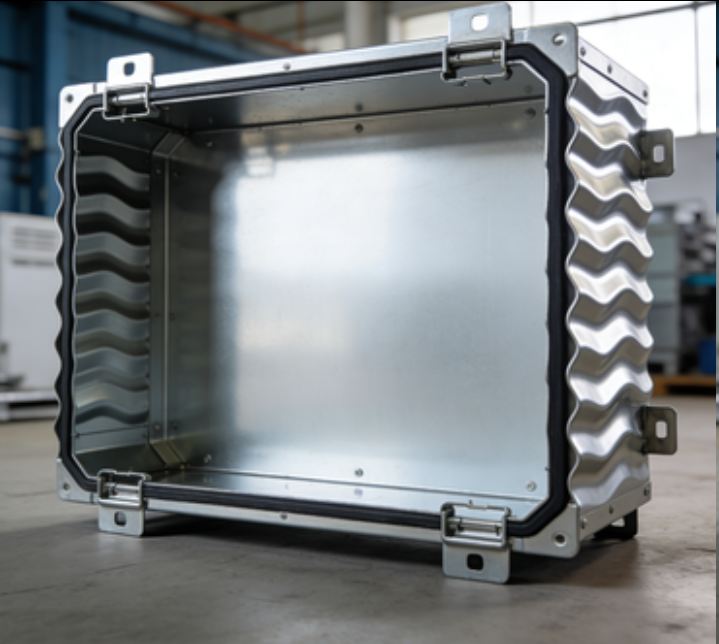

Stamping parts are a fundamental component in the manufacturing of air conditioner (AC) outdoor unit panels—structural and protective covers that shield the unit’s compressors, condensers, and fan systems from external damage, weather, and debris. AC outdoor units operate in harsh outdoor environments year-round, exposed to rain, snow, extreme temperatures (from -20°C in winter to 50°C in summer), and UV radiation. As such, their panels require exceptional durability, corrosion resistance, and structural rigidity—qualities that stamping technology efficiently delivers through precise metal forming and material optimization.

Material selection for stamped AC outdoor unit panels prioritizes weather resistance and mechanical strength. The most common material is galvanized steel (with a zinc coating thickness of 60–100 μm), which provides robust corrosion protection against rain and humidity. For higher-end AC models or units installed in coastal areas (exposed to salt spray), aluminum-zinc alloy-coated steel (e.g., Galvalume) is preferred; it offers 2–3 times better corrosion resistance than standard galvanized steel and maintains structural integrity even after years of UV exposure. Some manufacturers also use aluminum alloy (e.g., 3003-H14) for lightweight panels, which reduces the unit’s overall weight and simplifies installation, while still offering sufficient strength to withstand wind loads of up to 120 km/h.

The stamping process enables the creation of panels with integrated functional and protective features. Custom dies can form louvered vents—precision-cut slits that allow airflow to the condenser (critical for heat dissipation) while preventing large debris (like leaves or small branches) from entering the unit. These louvers are stamped at a 30–45° angle to balance airflow efficiency (ensuring 80%+ air permeability) and debris protection. Stamping also forms reinforced edges and ribs along the panel’s perimeter and surface; these ribs increase the panel’s bending resistance by 50–60% compared to flat sheets, preventing warping under heavy snow loads or strong winds. For example, a stamped galvanized steel panel with 5mm-wide reinforcing ribs can support up to 15 kg of snow per square meter without deformation.

Precision is critical for panel assembly, as outdoor units require tight fits to prevent water ingress and ensure structural stability. Stamping achieves dimensional tolerances of ±0.1mm for panel dimensions (e.g., 900mm × 1200mm for a typical 2-ton AC unit), ensuring that panels align perfectly with the unit’s frame and other components. Stamped holes for mounting bolts (e.g., M6 or M8 diameter) are positioned with ±0.05mm accuracy, allowing for quick and secure assembly on the production line. Additionally, stamping can form folded flanges along the panel’s edges—these flanges create a sealed overlap with adjacent panels, reducing gaps where water or dust could enter the unit’s interior.

Post-stamping treatments further enhance the panel’s durability and appearance. After stamping, panels undergo powder coating—a process where a thermosetting polymer coating is applied and cured at 180–200°C. This coating provides a scratch-resistant, UV-stable finish that maintains color consistency (resisting fading) for 5–8 years. The powder coating also adds an extra layer of corrosion protection, ensuring the panel remains rust-free even in high-humidity environments. Some panels also receive a hydrophobic coating, which causes rainwater to bead and run off quickly, reducing moisture accumulation on the surface.

Cost-effectiveness is a key advantage for AC manufacturers, who produce millions of outdoor units annually. Stamping lines can produce 300–500 panels per hour, with material utilization rates of 85–90% (achieved through optimized nesting of panel shapes on metal sheets). This high-volume production keeps unit costs low—stamped panels are 40–50% cheaper than panels made via welding or casting—making AC units more accessible for residential and commercial consumers.

stamped AC outdoor unit panels combine weather resistance, structural strength, precision, and cost efficiency—essential qualities for protecting critical AC components and ensuring long-term unit performance. As AC technology advances toward higher energy efficiency and durability, stamping will remain a vital manufacturing method for outdoor unit panels.

Read recommendations:

Sealing ring Precision electronic parts

Housing components for recessed downlights Precision electronic parts

Oval Magnetic Hardware Precision electronic parts