Time:2025-06-10 Views:0 source:CNC Machining customization source:CNC Machining news

Regular maintenance and proper service of CNC equipment are essential for ensuring its reliable operation, extending its lifespan, and maintaining high - quality machining performance. Establishing appropriate maintenance cycles and implementing effective maintenance methods are crucial steps in this process.

Maintenance Cycle Determination

The maintenance cycle of CNC equipment depends on various factors, such as the type of machine, usage frequency, working environment, and manufacturer's recommendations. For machines that operate continuously in harsh environments, such as those in foundries or machining shops with high dust and metal debris, more frequent maintenance is required. Generally, daily, weekly, monthly, quarterly, and annual maintenance cycles are established. Daily maintenance mainly focuses on visual inspections, such as checking the lubrication oil levels, coolant levels, and the presence of any abnormal noises or vibrations. Weekly maintenance may include more in - depth inspections of the machine's moving parts, such as ball screws and linear guides, to check for wear and proper lubrication. Monthly maintenance often involves cleaning the machine's electrical cabinets, checking the connections of electrical components, and inspecting the tool - holding system. Quarterly and annual maintenance are more comprehensive, covering tasks like calibration of the machine axes, replacement of filters, and overall performance evaluation.

Maintenance Methods

Lubrication: Proper lubrication is crucial for the smooth operation of CNC equipment. Different components, such as ball screws, linear guides, and spindles, require specific types of lubricants. Regularly applying the correct lubricant in the right amount can reduce friction, prevent wear, and extend the lifespan of these components. Some CNC machines are equipped with automatic lubrication systems that can dispense lubricant at pre - set intervals, but manual lubrication may still be required for certain parts.

Cleaning: Keeping the CNC machine clean is essential to prevent the accumulation of dust, chips, and coolant residues, which can cause damage to the machine's components. Regularly clean the worktable, guideways, and electrical cabinets using appropriate cleaning tools and solvents. For example, compressed air can be used to blow away chips from the work area, while a mild cleaning solution can be used to remove stubborn stains from the machine's surface.

Electrical System Maintenance: The electrical system of a CNC machine is complex and critical. Regularly check the electrical connections for tightness and signs of corrosion. Inspect the fuses, relays, and circuit breakers to ensure they are in good working condition. Clean the electrical cabinets to prevent dust from interfering with the electrical components. Additionally, backup the machine's control system software regularly to prevent data loss in case of system failures.

Component Inspection and Replacement: Periodically inspect key components of the CNC machine, such as the spindle, servo motors, and ball screws, for signs of wear or damage. Replace worn - out components in a timely manner to avoid further damage to the machine. For example, if a ball screw shows excessive play or uneven movement, it should be replaced immediately to maintain the machine's accuracy.

Training and Documentation

Properly trained operators and maintenance personnel are essential for effective CNC equipment maintenance. Provide regular training to staff on the correct operation, maintenance procedures, and safety precautions of the CNC machine. In addition, maintain detailed documentation of the machine's maintenance history, including the date of maintenance, tasks performed, and any component replacements. This documentation can help in tracking the machine's performance over time, identifying recurring problems, and planning future maintenance activities.

establishing appropriate maintenance cycles and implementing effective maintenance methods are key to keeping CNC equipment in good working condition. By following these practices, manufacturers can minimize downtime, reduce repair costs, and ensure the long - term reliability and performance of their CNC equipment.

Read recommendations:

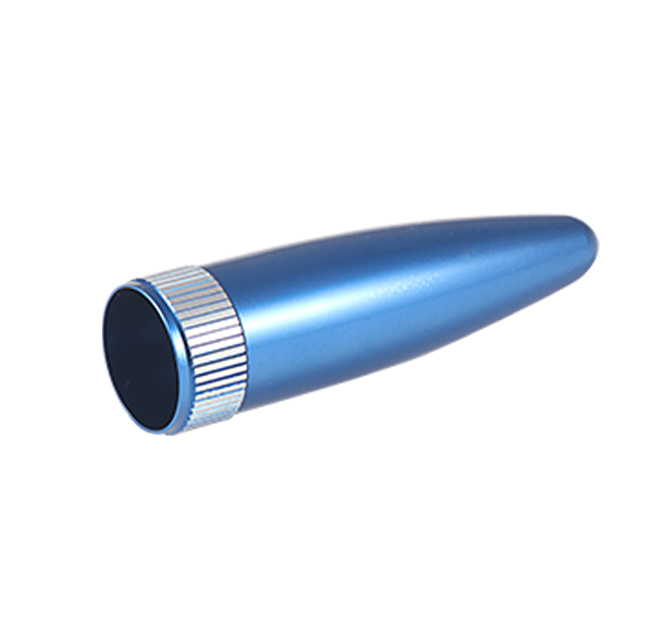

Sealing ring Precision electronic parts

Housing components for recessed downlights Precision electronic parts

Oval Magnetic Hardware Precision electronic parts