Time:2026-01-07 Views:0 source:CNC Machining customization source:CNC Machining news

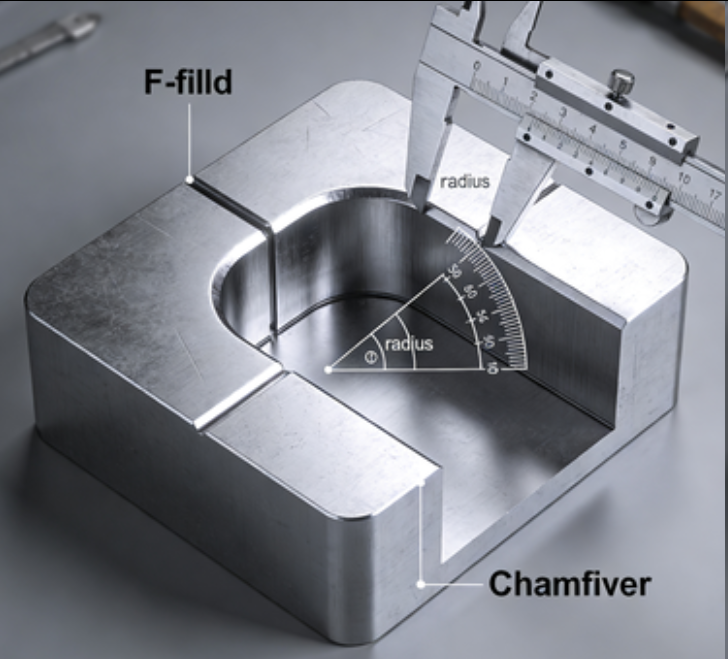

In the manufacturing of stamping parts, the incorporation of R - fillets and chamfering techniques is of great significance, as they not only enhance the aesthetic appeal but also improve the functional performance and durability of the parts. An R - fillet, also known as a rounded corner, is a curved transition between two surfaces of a stamping part, while chamfering creates a beveled edge. Both features play important roles in different aspects of part design and manufacturing.

R - fillets are widely used to reduce stress concentrations. Similar to chamfering, sharp corners on stamping parts can be areas of high stress, especially when the parts are subjected to mechanical loads, vibrations, or thermal changes. By introducing an R - fillet, the stress is distributed more evenly across the corner, minimizing the risk of crack initiation and propagation. This is particularly crucial in industries such as aerospace, where the reliability and safety of components are of utmost importance. For example, in aircraft structural stamping parts, R - fillets are carefully designed and manufactured to ensure that the parts can withstand the extreme forces experienced during flight.

In addition to stress reduction, R - fillets can also improve the flow of materials during the stamping process. In metal stamping, when the sheet metal is deformed to form the part, a rounded corner allows for a smoother transition of the material, reducing the likelihood of wrinkles, cracks, or other defects. This results in higher - quality parts with fewer manufacturing flaws. Moreover, R - fillets can enhance the visual appearance of stamping parts, making them more appealing in consumer products. For instance, in the production of metal furniture or decorative components, R - fillets give the parts a sleek and modern look.

Chamfering, when combined with R - fillets, further optimizes the performance of stamping parts. As mentioned before, chamfering helps with part assembly and stress relief. When both R - fillets and chamfers are present on a stamping part, they work in tandem to create a more functional and reliable component. The manufacturing processes for R - fillets and chamfering involve precise control of cutting tools, machining parameters, and material properties. Advanced CAD/CAM software is often used to design these features accurately, and CNC machining or specialized stamping dies are employed to achieve the desired shapes with high precision. Quality control measures, such as dimensional inspection and surface finish evaluation, are essential to ensure that the R - fillets and chamfers meet the specified requirements, contributing to the overall excellence of the stamping parts.

Read recommendations:

Sealing ring Precision electronic parts

Housing components for recessed downlights Precision electronic parts

Oval Magnetic Hardware Precision electronic parts