Time:2025-09-05 Views:0 source:CNC Machining customization source:CNC Machining news

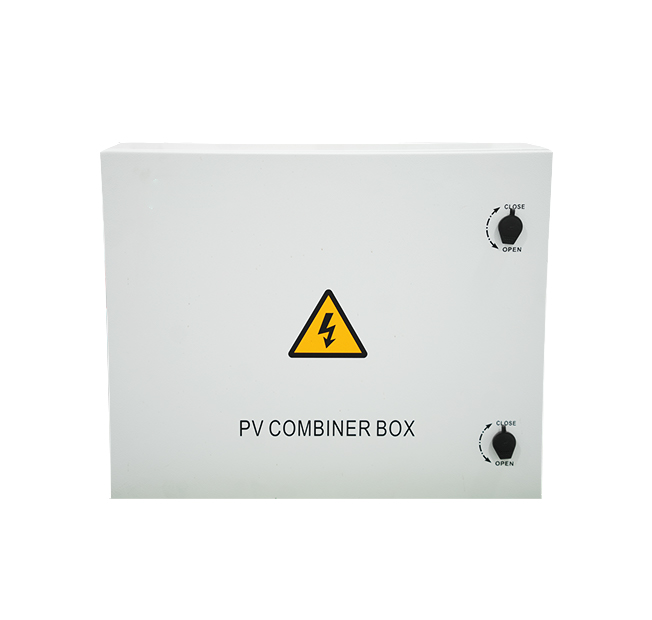

Sheet metal instrument enclosures are crucial protective casings for a wide range of instruments, providing both physical protection and functional support. These enclosures are designed to safeguard delicate internal components from external factors such as dust, moisture, impacts, and electromagnetic interference, while also facilitating proper operation and maintenance of the instruments.

The design of sheet metal instrument enclosures begins with a comprehensive understanding of the instrument's requirements. Factors such as the size and shape of internal components, the need for ventilation, access points for controls and connectors, and the environmental conditions in which the instrument will operate all influence the enclosure's design. For example, in industrial settings, instruments are often exposed to harsh environments with high levels of dust and vibrations. Sheet metal enclosures for such instruments are typically constructed from durable materials like stainless steel or thick - gauge aluminum. These materials offer excellent resistance to corrosion and mechanical damage, ensuring the long - term reliability of the instrument.

Manufacturing sheet metal instrument enclosures involves a series of precise processes. Initially, sheet metal is cut to the required size and shape using techniques such as laser cutting or punching. Then, bending operations are carried out to form the various sides and features of the enclosure. Welding or riveting is used to join the individual parts together, creating a sturdy and seamless structure. To enhance functionality, enclosures may incorporate features like ventilation slots, which are designed to dissipate heat generated by internal components. These slots are carefully positioned and sized to ensure optimal airflow while preventing the entry of dust and debris. Additionally, cutouts for buttons, displays, and connectors are accurately fabricated to ensure a perfect fit with the instrument's controls and interfaces.

In terms of aesthetics, sheet metal instrument enclosures can be customized to meet specific branding and design requirements. Surface finishing techniques such as powder coating or anodizing not only provide protection against corrosion but also offer a wide range of colors and textures. This allows the enclosures to blend seamlessly with the overall design of the instrument and the surrounding environment. Whether it's for a high - tech laboratory instrument or a rugged industrial control panel, sheet metal instrument enclosures play a vital role in ensuring the performance, durability, and usability of the instruments they house.

Read recommendations:

Sealing ring Precision electronic parts

Housing components for recessed downlights Precision electronic parts

Oval Magnetic Hardware Precision electronic parts