Time:2025-06-06 Views:0 source:CNC Machining customization source:CNC Machining news

Surface hardening treatment processes are essential for improving the wear resistance, fatigue strength, and overall durability of stamping parts. These processes focus on altering the surface properties of the part while maintaining the ductility and toughness of the core material.

One widely used surface hardening method is case hardening. Case hardening includes techniques such as carburizing, nitriding, and carbonitriding. Carburizing involves heating the stamping part in a carbon - rich atmosphere, causing carbon to diffuse into the surface layer. This increases the carbon content at the surface, resulting in a harder and more wear - resistant layer. After carburizing, the part is usually quenched and tempered to achieve the desired hardness and toughness combination. Nitriding, on the other hand, introduces nitrogen into the surface layer of the part. Nitrided surfaces have excellent wear resistance, corrosion resistance, and fatigue strength, making them suitable for parts that are subject to high - stress and friction, such as gears and shafts.

Induction hardening is another popular surface hardening process. In induction hardening, the stamping part is placed in a coil through which an alternating current is passed. The electromagnetic field generated by the coil induces eddy currents in the part, which in turn generate heat. The surface of the part heats up rapidly, and then it is quenched to harden the surface layer. Induction hardening offers precise control over the depth and hardness of the hardened layer, making it suitable for parts with complex geometries.

Laser surface hardening is a more advanced technique. A high - power laser beam is used to heat the surface of the stamping part to a high temperature, followed by rapid self - quenching as the heat conducts into the cooler core of the part. Laser surface hardening can produce a very hard and wear - resistant surface layer with minimal distortion of the part. It also allows for selective hardening, enabling the treatment of specific areas of the part according to its functional requirements. These surface hardening treatment processes for stamping parts are crucial for extending the service life and improving the performance of components in various industrial applications.

Read recommendations:

Sealing ring Precision electronic parts

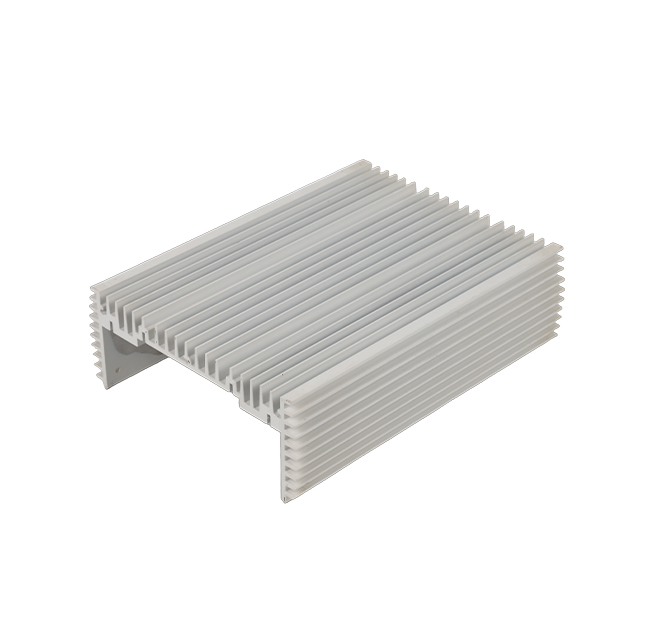

Housing components for recessed downlights Precision electronic parts

Oval Magnetic Hardware Precision electronic parts