Time:2025-08-08 Views:0 source:CNC Machining customization source:CNC Machining news

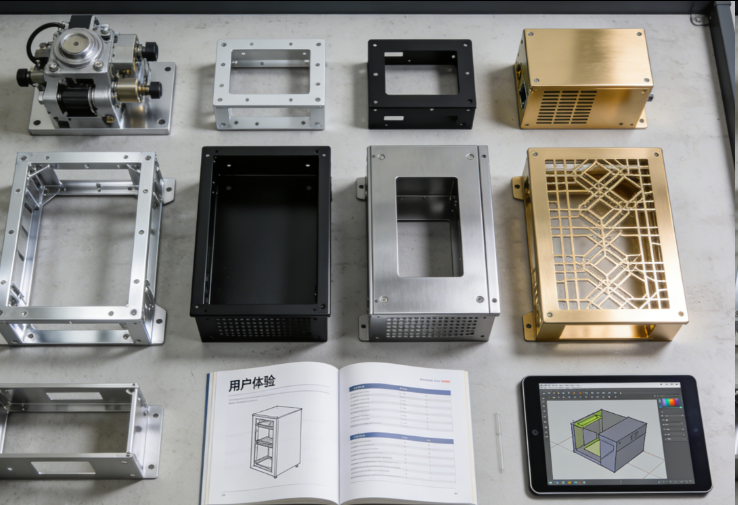

Customized sheet metal products play a pivotal role in meeting the unique needs of various industries, from automotive and aerospace to electronics and construction. This service involves tailoring sheet metal components to specific dimensions, shapes, and functional requirements, ensuring they seamlessly integrate into the end product or system. Manufacturers leverage advanced design software, such as CAD (Computer-Aided Design), to translate client specifications into precise blueprints, which are then used to guide cutting, bending, welding, and finishing processes.

One of the key advantages of customized sheet metal products is their ability to address complex or non-standard applications. For example, in the aerospace industry, where weight reduction and structural integrity are critical, customized sheet metal parts can be engineered to minimize mass while withstanding extreme pressure and temperature fluctuations. Similarly, in the electronics sector, custom enclosures and brackets are designed to protect sensitive components from environmental factors like dust, moisture, and electromagnetic interference.

Material selection is a crucial aspect of customization, with manufacturers offering a range of options including stainless steel, aluminum, galvanized steel, and copper, each chosen based on the application’s requirements for durability, corrosion resistance, conductivity, or cost. For instance, stainless steel is preferred for food processing equipment due to its hygiene and rust resistance, while aluminum is favored in automotive parts for its lightweight properties.

The customization process also involves choosing appropriate surface finishes to enhance both aesthetics and functionality. Options include painting, powder coating, galvanizing, and anodizing, which not only improve the product’s appearance but also provide additional protection against wear, corrosion, and UV damage. This attention to detail ensures that customized sheet metal products not only meet technical specifications but also align with the client’s branding or design preferences.

Flexibility in production volume is another benefit of customized sheet metal services. Whether a client requires a single prototype or large-scale production runs, manufacturers can adjust their processes to accommodate varying quantities, ensuring cost-effectiveness and timely delivery. This scalability makes customized sheet metal products suitable for both small businesses and large corporations, supporting innovation and product development across industries.

customized sheet metal products offer tailored solutions that combine precision engineering, material expertise, and flexible production to meet the diverse needs of modern industries. By focusing on client-specific requirements, manufacturers deliver components that enhance the performance, reliability, and longevity of the end products they serve.

Read recommendations:

Sealing ring Precision electronic parts

Housing components for recessed downlights Precision electronic parts

Oval Magnetic Hardware Precision electronic parts