Time:2026-01-05 Views:0 source:CNC Machining customization source:CNC Machining news

CNC (Computer Numerical Control) machining has revolutionized the production of agricultural equipment parts, offering unparalleled precision, efficiency, and flexibility in manufacturing components crucial for modern farming operations. Agricultural equipment, ranging from tractors and harvesters to irrigation systems, demands parts that can withstand harsh environmental conditions, heavy loads, and continuous use. CNC machining provides the means to produce high - quality, durable parts that meet these exacting requirements.

One of the key advantages of CNC machining for agricultural equipment parts is its ability to work with a wide variety of materials. Metals such as steel, aluminum, and cast iron are commonly used in agricultural machinery due to their strength and durability. CNC machines can precisely cut, mill, and drill these materials to create complex geometries with tight tolerances. For example, in the production of tractor axles, CNC machining ensures that the components are manufactured to exact specifications, providing the necessary strength to support heavy loads while maintaining smooth operation. Additionally, CNC machining can also handle non - metallic materials like high - strength plastics and composites, which are increasingly being used in agricultural equipment for their lightweight and corrosion - resistant properties.

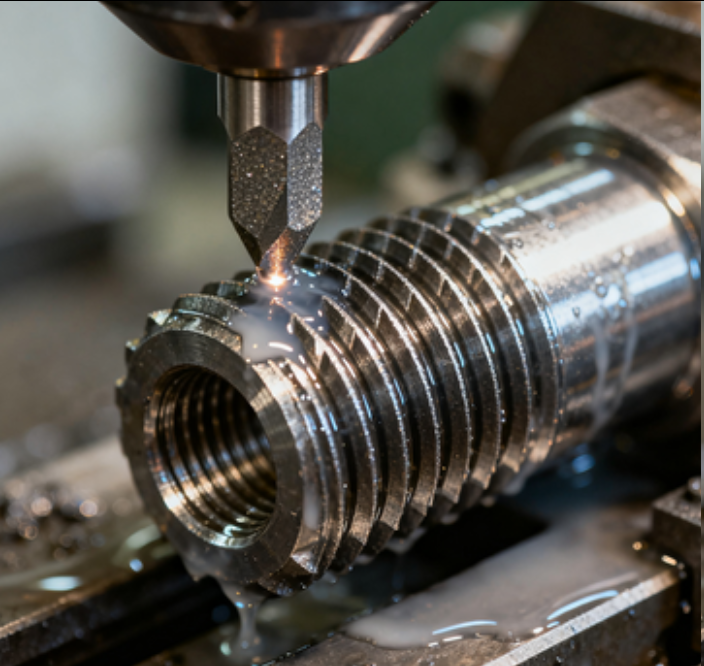

The precision of CNC machining is particularly important for agricultural equipment parts. Components such as engine blocks, transmission gears, and hydraulic fittings require precise dimensions to ensure proper fit and function. CNC machines use computer - controlled tools that follow programmed instructions, eliminating human error and ensuring consistent quality across large production runs. This precision also allows for the creation of intricate designs and features that enhance the performance of agricultural equipment. For instance, CNC - machined irrigation nozzles can be designed with specific flow patterns to optimize water distribution, improving crop yields while conserving water resources.

Another benefit of CNC machining in the agricultural sector is its efficiency. Once the machining program is developed, CNC machines can produce parts quickly and continuously, reducing production time and costs. This is especially important during the farming season when there is a high demand for replacement parts. Moreover, CNC machining enables the production of custom - made parts, allowing farmers and equipment manufacturers to address specific needs or modify existing equipment. Whether it's creating a unique adapter for a specialized attachment or fabricating a replacement part for an older piece of machinery, CNC machining provides the flexibility to meet diverse requirements. In summary, CNC machining plays a vital role in the production of agricultural equipment parts, enabling the creation of high - quality, precise, and efficient components that are essential for modern agricultural operations.

Read recommendations:

Sealing ring Precision electronic parts

Housing components for recessed downlights Precision electronic parts

Oval Magnetic Hardware Precision electronic parts