Time:2025-06-17 Views:0 source:CNC Machining customization source:CNC Machining news

Key Points of CNC Plastic Parts Processing for Home Appliances

CNC plastic parts processing for home appliances has its own unique set of key points that need to be considered to produce high - quality, functional, and aesthetically pleasing components. These points involve aspects such as material selection, process optimization, and surface treatment.

Material Selection for Functionality and Aesthetics

The choice of plastic materials for home appliance parts depends on their intended functions and the desired aesthetic appearance. For components that require high impact resistance, such as the outer casings of washing machines and refrigerators, engineering plastics like acrylonitrile butadiene styrene (ABS) are commonly used. ABS offers a good balance of strength, toughness, and ease of processing. It can be easily molded into complex shapes and is available in a wide range of colors, allowing for customization of the appliance's appearance. Polypropylene (PP) is another popular choice for parts that come into contact with food, such as the inner drawers of refrigerators, due to its excellent chemical resistance, hygiene properties, and heat resistance. Additionally, the material's melt flow index (MFI) needs to be carefully considered, as it affects the ease of processing and the quality of the final part. A proper MFI ensures that the plastic can flow smoothly during CNC machining processes like injection molding or 3D printing, reducing the occurrence of defects such as short shots or warping.

Efficient process planning is crucial for CNC plastic parts processing. Injection molding is one of the most widely used processes for manufacturing home appliance plastic parts. Optimizing the injection molding process involves factors such as mold design, injection temperature, pressure, and cooling time. The mold design should be carefully engineered to ensure proper filling of the cavity, uniform cooling, and easy part ejection. The injection temperature needs to be set at an appropriate level to ensure that the plastic melts completely without degrading. Too high a temperature can cause the plastic to decompose, while too low a temperature may result in poor part quality. Pressure control is also important to ensure that the plastic fills all the details of the mold cavity. Adequate cooling time is necessary to allow the part to solidify properly, preventing warping and deformation. In addition to injection molding, CNC machining techniques like milling and turning can be used for post - processing operations, such as trimming excess material, creating precise holes, or adding surface textures. These operations need to be carefully coordinated with the injection molding process to ensure overall efficiency and part quality.

Surface Treatment for Aesthetics and Durability

Surface treatment plays a significant role in enhancing the appearance and durability of home appliance plastic parts. Painting is a common surface treatment method, which can provide a wide range of colors and finishes, from glossy to matte. Specialized paints with good adhesion, scratch resistance, and UV resistance are used to ensure that the parts maintain their appearance over time. Another popular treatment is surface texturing, which can add visual interest and also improve the grip of the parts. Texturing can be achieved through methods such as chemical etching, laser engraving, or using textured molds during injection molding. Additionally, coatings like anti - fingerprint coatings can be applied to parts that are frequently touched, such as refrigerator door handles, to keep them looking clean and new. These surface treatment processes need to be carefully integrated into the overall manufacturing process to ensure that they do not compromise the functionality or structural integrity of the plastic parts.

the key points of CNC plastic parts processing for home appliances revolve around material selection, process optimization, and surface treatment. By paying close attention to these aspects, manufacturers can produce plastic parts that meet the high - quality standards and aesthetic requirements of the home appliance industry.

Read recommendations:

Sealing ring Precision electronic parts

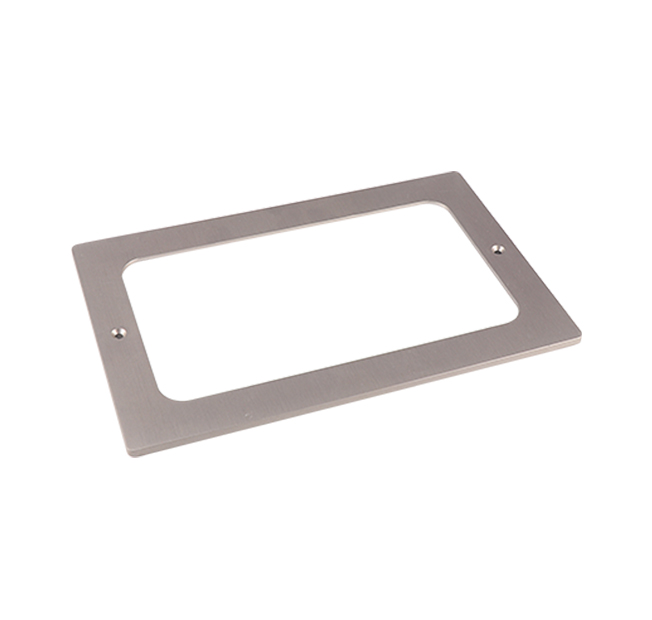

Housing components for recessed downlights Precision electronic parts

Oval Magnetic Hardware Precision electronic parts