Time:2026-01-15 Views:0 source:CNC Machining customization source:CNC Machining news

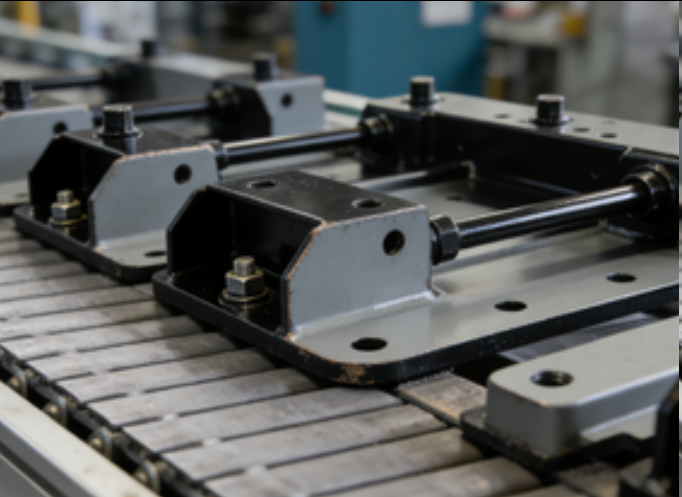

Electrophoretic coating, also known as electrocoating, is a highly advanced and efficient surface finishing process specifically tailored for stamping parts. This technique has revolutionized the way stamping parts are protected and enhanced, offering a multitude of benefits that are crucial in various industries.

The electrophoretic coating process begins with the preparation of the stamping parts. They are meticulously cleaned to remove any dirt, oil, grease, or other contaminants that could interfere with the coating process. This pre - treatment step is essential as it ensures optimal adhesion of the coating to the surface of the parts. Once cleaned, the stamping parts are immersed in a bath containing water - based paint particles that are charged with an electric current. The parts themselves are connected to an electrode, creating an electric field within the bath. Through the principle of electrophoresis, the charged paint particles are attracted to the surface of the stamping parts, forming a uniform and continuous coating layer. After the coating is applied, the parts are baked in an oven at a specific temperature. This curing process hardens the coating, enhancing its durability, hardness, and chemical resistance.

One of the most significant advantages of electrophoretic coating for stamping parts is its ability to provide an even and consistent coating, even on complex - shaped parts with intricate geometries and hard - to - reach areas. This is in contrast to traditional coating methods, which may struggle to cover all surfaces uniformly. The resulting coating offers excellent corrosion protection, safeguarding the stamping parts from rust and other forms of environmental degradation. It also provides a smooth and aesthetically pleasing finish, which is highly desirable in industries such as automotive, where appearance matters. Moreover, electrophoretic coating is an environmentally friendly process as it uses water - based paints, reducing the emission of volatile organic compounds (VOCs) compared to solvent - based coating methods.

Read recommendations:

Sealing ring Precision electronic parts

Housing components for recessed downlights Precision electronic parts

Oval Magnetic Hardware Precision electronic parts