Time:2025-12-27 Views:0 source:CNC Machining customization source:CNC Machining news

Stamping Parts Prototype Production refers to the process of creating small-batch, custom stamping parts to validate design concepts, test performance, and ensure compatibility before full-scale manufacturing. This stage is critical for businesses across industries—from automotive to consumer electronics— as it allows for early identification of design flaws (e.g., dimensional mismatches, structural weaknesses) and reduces the risk of costly rework during mass production. Unlike mass-produced stamping parts that rely on high-volume presses and permanent dies, prototype production often uses flexible manufacturing methods, such as CNC stamping or laser cutting combined with manual finishing, to accommodate frequent design iterations.

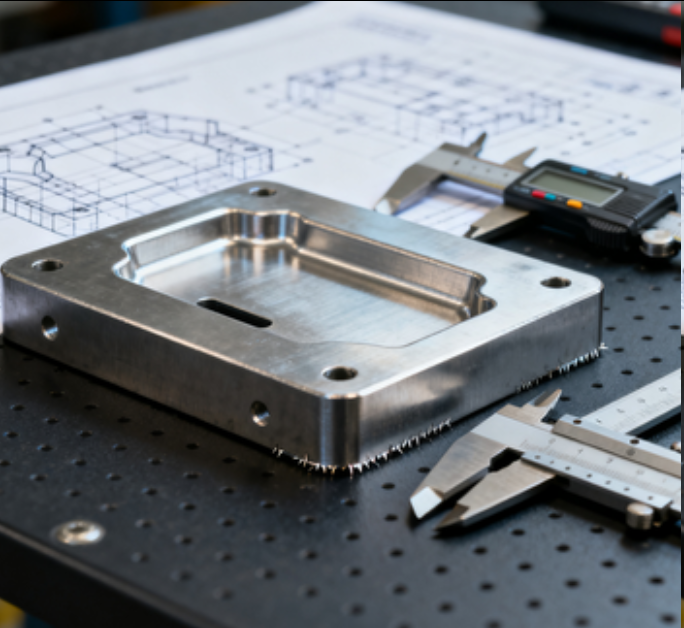

The process typically begins with design optimization: engineers refine 3D models of the stamping part to ensure it meets functional requirements (e.g., load-bearing capacity, fit with adjacent components) and is compatible with stamping processes. Next, a temporary or modular die is created—often from aluminum (for lower cost and faster production) rather than steel—to shape the metal material (commonly cold-rolled steel, aluminum, or stainless steel). The stamping process for prototypes may involve blanking (cutting the metal sheet to size), bending (forming angles or curves), or punching (creating holes or notches), with post-processing steps like deburring (removing sharp edges) and surface treatment (e.g., powder coating or anodizing) to mimic the final product’s appearance and durability.

For example, an automotive manufacturer developing a new stamped metal bracket for a car door would first produce 10–20 prototypes to test how the bracket withstands vibration, fits with the door frame, and interacts with other components like hinges. If the prototype fails a load test, engineers can adjust the bracket’s thickness or design and produce a new batch quickly—without investing in a permanent steel die. The precision of prototype stamping is crucial, with tolerances typically held within ±0.1mm to ensure the prototype accurately represents the final part. Whether used for validating a new consumer electronics component or testing an industrial machinery part, Stamping Parts Prototype Production serves as a vital bridge between design and mass production, ensuring the final product meets quality and performance standards.

Read recommendations:

Sealing ring Precision electronic parts

Housing components for recessed downlights Precision electronic parts

Oval Magnetic Hardware Precision electronic parts