Time:2025-06-10 Views:0 source:CNC Machining customization source:CNC Machining news

Optimizing the processing technology of CNC milling machines is essential for enhancing production efficiency, reducing costs, and improving the quality of machined parts. Several effective methods can be employed to achieve this goal, covering aspects from process planning to parameter adjustment.

Process Planning and Sequencing

Efficient process planning is the foundation of optimization. First, a detailed analysis of the part drawing is required to determine the best machining sequence. For complex parts, breaking down the machining process into roughing, semi - finishing, and finishing operations can improve both efficiency and accuracy. Roughing operations are designed to remove the majority of the excess material quickly, using larger cutting depths and feed rates. Semi - finishing operations then refine the shape and dimensions, leaving a small amount of stock for the final finishing. This separation of operations allows for the use of different tools and cutting parameters optimized for each stage. For example, in machining a cavity in a metal part, a large - diameter end - mill can be used for roughing, followed by a smaller, more precise end - mill for finishing to achieve the required surface finish and dimensional accuracy.

Tool Selection and Management

Proper tool selection, as mentioned before, is crucial. Additionally, effective tool management can optimize the machining process. Tools should be selected based on the material being machined, the machining operation, and the machine's capabilities. Using the right tool for each task can reduce machining time and improve surface quality. Tool life prediction and replacement scheduling are also important. By monitoring tool wear during machining and replacing tools before they reach the end of their useful life, unexpected tool failures and poor - quality parts can be avoided. Some advanced CNC systems even have built - in tool - monitoring functions that can detect tool wear and provide alerts for timely replacement.

Cutting Parameter Optimization

Optimizing cutting parameters, such as spindle speed, feed rate, and cutting depth, can significantly impact the machining process. These parameters should be adjusted according to the material properties, tool type, and machining operation. For example, when machining aluminum, higher spindle speeds and feed rates can be used compared to steel due to aluminum's lower hardness. However, increasing the feed rate too much may result in poor surface finish or tool breakage. Therefore, a balance must be struck. Many CNC machines now come with software that can recommend optimal cutting parameters based on the input material and tool data. Additionally, trial - and - error testing on sample parts can help fine - tune these parameters for specific machining tasks.

Fixture and Workholding Optimization

The design and use of fixtures and workholding devices can also affect the machining process. A well - designed fixture can ensure proper part positioning and clamping, reducing the risk of vibration and deflection during machining. This, in turn, improves machining accuracy and surface quality. For example, using vacuum chucks for holding thin - walled plastic parts can prevent deformation caused by traditional clamping methods. Moreover, quick - change fixtures can reduce setup times, increasing the overall productivity of the CNC milling machine.

optimizing the processing technology of CNC milling machines involves comprehensive strategies in process planning, tool management, cutting parameter adjustment, and fixture design. By implementing these optimization methods, manufacturers can achieve higher - quality parts, shorter production cycles, and increased competitiveness in the market.

Read recommendations:

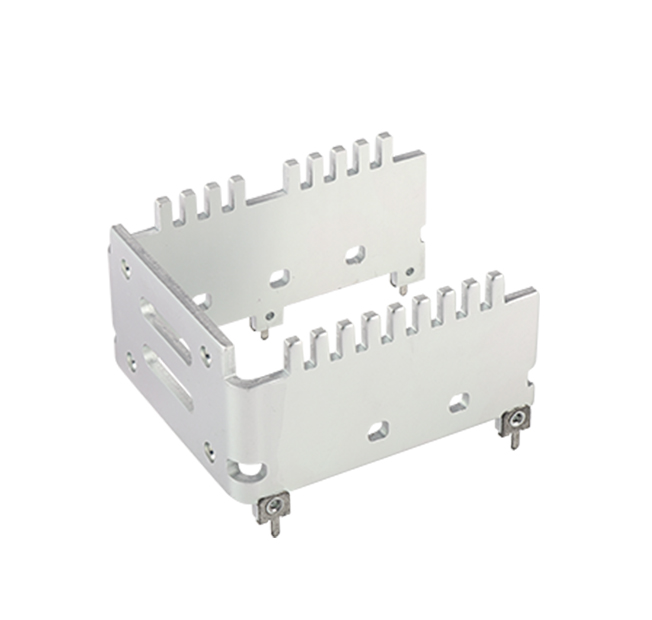

Sealing ring Precision electronic parts

Housing components for recessed downlights Precision electronic parts

Oval Magnetic Hardware Precision electronic parts