Time:2025-10-30 Views:0 source:CNC Machining customization source:CNC Machining news

Automobile chassis components are the foundation of a vehicle's structural integrity and performance, and stamping parts play an indispensable role in their fabrication. The chassis, which supports the vehicle's body and houses critical systems such as the suspension, steering, and braking systems, demands parts that are not only robust but also precisely engineered to ensure optimal functionality and safety on the road.

Material selection for stamping parts used in automobile chassis components is a meticulous process. High - strength steel alloys are predominantly favored due to their exceptional load - bearing capabilities. These steels can endure the significant stresses and strains exerted by the vehicle's weight, the forces generated during acceleration, braking, and cornering, as well as the impact from uneven road surfaces. For instance, components like chassis frames, cross - members, and control arms are often stamped from high - strength steel. In recent years, advanced high - strength steels (AHSS) and ultra - high - strength steels (UHSS) have gained popularity. AHSS offers a better strength - to - weight ratio, enabling the production of lighter yet stronger chassis parts, which in turn improves fuel efficiency. UHSS, with its extremely high tensile strength, is crucial for components that need to withstand severe impacts, enhancing the vehicle's crashworthiness.

The stamping process for automobile chassis components is highly automated and sophisticated. Large - tonnage stamping presses are employed to shape metal sheets into the required forms. Progressive die stamping is commonly used for mass - producing multiple related parts in a single operation, streamlining the production process and ensuring consistent quality. Transfer die stamping, on the other hand, is utilized for more complex chassis components that require multiple forming steps. Precision in stamping is of utmost importance, as even the slightest deviation in the dimensions of chassis parts can affect the alignment of the suspension and steering systems, leading to poor handling and safety issues.

Functionally, stamping parts in automobile chassis components contribute significantly to the vehicle's performance. For example, well - designed and precisely stamped control arms are essential for maintaining proper wheel alignment and ensuring smooth suspension operation. They allow the wheels to move up and down freely while keeping the tires in optimal contact with the road surface. Additionally, stamped cross - members help to reinforce the chassis, reducing flex and vibrations, which improves the vehicle's stability and ride comfort. In terms of safety, the strength and integrity of stamped chassis parts are vital. They form the first line of defense during a collision, absorbing and distributing impact forces to protect the passenger compartment. Overall, stamping parts are integral to the production of reliable, high - performing, and safe automobile chassis components.

Read recommendations:

Sealing ring Precision electronic parts

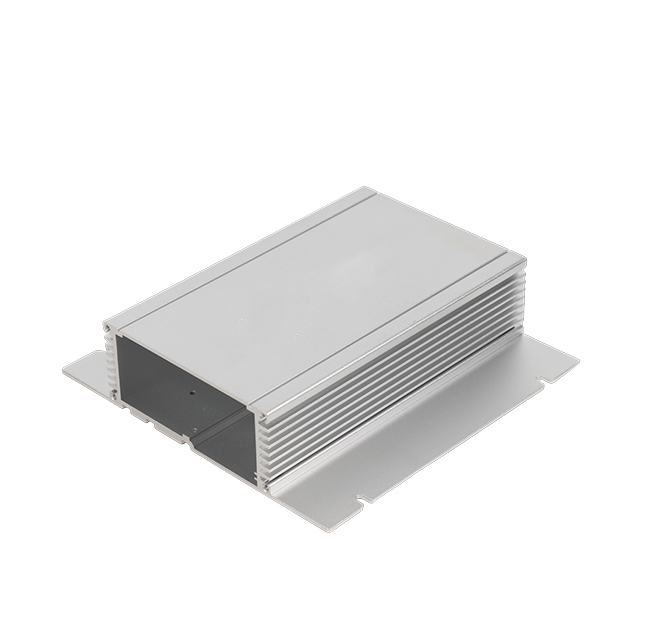

Housing components for recessed downlights Precision electronic parts

Oval Magnetic Hardware Precision electronic parts